Each year as kids head back to school in modular and portable classroom buildings there are instances of unsafe site conditions. Here are a few tips to keep your project site safer and keep the children and staff out of the nurses office with avoidable accidents:

( 5 ) Great tips for safety:

1. If you have wall mounted mechanical units that usually sit 4' - 5' off the ground implement safety plan:

* Build a cage or designer box around the mechanical units (pretty also)

* Put in pipe bollards painted yellow to warn pedestrian traffic of possible danger

* Pull your sidewalks and walkways away from the modular building a minimum of 3' to remove the pedestrian pathway away from the mechanical units

2. If you have a ramp, make sure there is no rust or broken sharp edges that can cut or hurt someone

2A. Do a preventative walk through of your ramp & stair attachments & make sure the railings are attached, the welds are tight, skid resistant material fresh coating.

3. If your doors swing "out" paint a circle on the sidewalks so kids and staff can visualize the swing radius

4. If you have traditional steel doors consider adding a "view lite" small window so when opening a door you can see oncoming pedestrian traffic

5. Of course, the traditional fire alarm,fire sprinkler, & extinguisher equipment need to pass annual inspections

For more information contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: Information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved copyright, trademark © 2014

Wednesday, August 27, 2014

Tuesday, August 26, 2014

Back To School, In A New Modular School

It is that time of year and the new school year is well underway in many locations. Schools are in session from head start to university level education. Many of those schools are back in session, in a modular building, or a modular campus. FLOOR PLAN LINK

Modular buildings are used for temporary overflow classrooms, and also as a permanent space solution. No matter what type of modular building is on your campus you can feel secure knowing the IBC construction code is incorporated into every new modular building going to a school campus. What type of modular buildings are on a school campus?

1. Traditional classrooms for 20 - 35 students each.

2. Science laboratories for accelerating STEM education

3. Computer learning labs, with advanced technologies

4. Vocational training labs (cosmetology, culinary arts,vehicle shop, etc)

5. Daycare and infant care centers

6. Lecture halls and conference centers

7. Cafeteria, food service, multipurpose facilities

8. Sports centers (gymnasium, locker rooms)

9. Specialty classroom (arts, music)

10. Administration offices

11. Bus barns and service bays

12. Guard Shacks/Security Booths

13. Health care and wellness centers or nursing stations

14. On line learning centers

No matter what the space need is on an educational campus, there is a Modular Solution!

For more information contact our team:

Modular Solutions, Ltd

P O Box 15507-Phoenix, AZ 85060

Phone: 800-441-8577 ext. 1

email: Information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark 2014 ©

Modular buildings are used for temporary overflow classrooms, and also as a permanent space solution. No matter what type of modular building is on your campus you can feel secure knowing the IBC construction code is incorporated into every new modular building going to a school campus. What type of modular buildings are on a school campus?

1. Traditional classrooms for 20 - 35 students each.

2. Science laboratories for accelerating STEM education

3. Computer learning labs, with advanced technologies

4. Vocational training labs (cosmetology, culinary arts,vehicle shop, etc)

5. Daycare and infant care centers

6. Lecture halls and conference centers

7. Cafeteria, food service, multipurpose facilities

8. Sports centers (gymnasium, locker rooms)

9. Specialty classroom (arts, music)

10. Administration offices

11. Bus barns and service bays

12. Guard Shacks/Security Booths

13. Health care and wellness centers or nursing stations

14. On line learning centers

No matter what the space need is on an educational campus, there is a Modular Solution!

For more information contact our team:

Modular Solutions, Ltd

P O Box 15507-Phoenix, AZ 85060

Phone: 800-441-8577 ext. 1

email: Information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark 2014 ©

Tuesday, August 19, 2014

Are Bars Safe?

Security is always an issue with any office facility. If you are rural you face weekend or passer by traffic stopping in to see what they can "borrow", if you are in a busy city you face the crime rates that goes along with being in a metropolitan area. One thing our clients are concerned about is what if they can not get out of a modular building in an emergency?

The key to security both internal and external is "DESIGN". Do not buy security bars from a vendor that will make your new facility look like a prison. We have found that there is an entire art to this industry. We work with one vendor , Desert Ornamental Artistry, and the reason we enjoy working with them is that they always provide decorative and creative solutions meeting the security aspects of a project without looking boring and common.

Some quick tips for design safety:

1. If you are getting an ornamental gate, have the door swing OUT. Safer for the occupant of a facility

2. If you are ordering security bars, make sure they have a "quick-release". This will release the bars in the

event of an internal safety issue such as fire or intruder.

3. Design your windows or at least one on a hallway large enough to use as an "egress" in an emergency. Small 12" tall windows are great for energy design,

but are not necessarily the best choice in an intruder situation.

4. Build your design creatively. Know that you have choices in the way the bars appear,

and how they are hung. You are not limited to vertical bars with mesh backing unless budget is your only concern.'

FOR MORE INFORMATION CONTACT OUR PRE-CONSTRUCITON TEAM:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: Information@mod-sol.com

Website: www.modularsolutionsltd.com

Linked In: ModularSolutionsLtd

all rights reserved, copyright, trademark 2014©

The key to security both internal and external is "DESIGN". Do not buy security bars from a vendor that will make your new facility look like a prison. We have found that there is an entire art to this industry. We work with one vendor , Desert Ornamental Artistry, and the reason we enjoy working with them is that they always provide decorative and creative solutions meeting the security aspects of a project without looking boring and common.

Some quick tips for design safety:

1. If you are getting an ornamental gate, have the door swing OUT. Safer for the occupant of a facility

2. If you are ordering security bars, make sure they have a "quick-release". This will release the bars in the

event of an internal safety issue such as fire or intruder.

3. Design your windows or at least one on a hallway large enough to use as an "egress" in an emergency. Small 12" tall windows are great for energy design,

but are not necessarily the best choice in an intruder situation.

4. Build your design creatively. Know that you have choices in the way the bars appear,

and how they are hung. You are not limited to vertical bars with mesh backing unless budget is your only concern.'

FOR MORE INFORMATION CONTACT OUR PRE-CONSTRUCITON TEAM:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: Information@mod-sol.com

Website: www.modularsolutionsltd.com

Linked In: ModularSolutionsLtd

all rights reserved, copyright, trademark 2014©

Friday, August 15, 2014

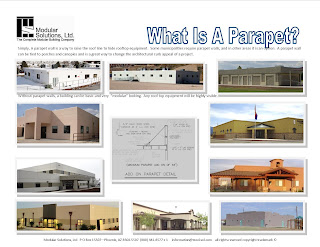

What Is A Parapet Wall?

When modular buildings are transported down the road they have to be within standard shipping heights allowed by the Department of Transportation. Additionally, sometimes the route to the project site has low overhead traffic lights or low bridges. Before any modular building goes down the road, the project manager will check the route to the site and see what type of height restrictions might be encountered, and if there is an alternative route. Modular companies that have a preconstruction team, will investigate these items during the design phase to avoid project surprises and expense.

What does all of this information have to do with a parapet wall? When clients want a higher profile modular building or have to hide mechanical roof top equipment they will add a parapet wall to raise the roof line and add architectural interest to the visual aspects of the modular building.

What is a parapet wall? The parapet wall can either be built on site, or in the plant, and is an addition that goes above he exterior perimeter walls. A parapet wall can be basic and squared off or a parapet wall can have fun architectural shapes. Parapet wall built in the plant will usually be 3' to 4' high so that the parapet walls can ship and install easily. Taller parapet walls are common but require additional design engineering.

For more information contact our team:

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark ©

What does all of this information have to do with a parapet wall? When clients want a higher profile modular building or have to hide mechanical roof top equipment they will add a parapet wall to raise the roof line and add architectural interest to the visual aspects of the modular building.

What is a parapet wall? The parapet wall can either be built on site, or in the plant, and is an addition that goes above he exterior perimeter walls. A parapet wall can be basic and squared off or a parapet wall can have fun architectural shapes. Parapet wall built in the plant will usually be 3' to 4' high so that the parapet walls can ship and install easily. Taller parapet walls are common but require additional design engineering.

For more information contact our team:

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark ©

Tuesday, August 12, 2014

Great Answers Are Usually Predicated By Great Questions

I have had clients come to Modular Solutions that were confused and shared with me that design-build construction was just too hard and did not make sense. Some clients have spent as much on architectural design as they have on the actual modular building structure. By asking the right questions, we can work together and establish what is important in the overall total package.

There are (3) basic areas that need to be Collaborated on:

Space Planning Goals, Structural Goals, and Budget.

Once the basics of those areas have been addressed and talked through clients can make informed design choices that lead to a better building plan in the end.

For more information on design-build modular construction contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved copyright, trademark 2014©

There are (3) basic areas that need to be Collaborated on:

Space Planning Goals, Structural Goals, and Budget.

Once the basics of those areas have been addressed and talked through clients can make informed design choices that lead to a better building plan in the end.

For more information on design-build modular construction contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved copyright, trademark 2014©

Monday, August 11, 2014

Going Green, With An Existing Modular Building

How can you reduce your carbon footprint when you are in an existing modular building? Here are a few tips to reduce your carbon footprint in an existing modular building.

TIPS TO REDUCE YOUR CARBON FOOTPRINT:

For more tips or to get a NEW MODULAR SOLUTION, contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutionsltd

all rights reserved 2014 ©

TIPS TO REDUCE YOUR CARBON FOOTPRINT:

For more tips or to get a NEW MODULAR SOLUTION, contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutionsltd

all rights reserved 2014 ©

Friday, August 8, 2014

GSA Advantage, Procurement Made Easy

If you are a federal agency and need space quickly, one of the best procurement tools is GSA advantage. Our Contract Number is GS-07F-0199L

How does GSA advantage work?

1. Find vendors and filter based on project qualifications (example geographic location, business size, reps & certs, etc)

2. Work out a scope or choose a design-build approach with best technical proposal winning the job

3. Set evaluation criteria to meet your goals (ie small business, disadvantaged enterprise, manufacturer, local preference, etc)

4. Post the notification and have all proposals back in within a few days or weeks (subject to technical criteria)

5. Pick your favorite team and get started!

Modular Solutions has successfully completed over $20M in GSA contracts with federal and eligible agencies.

If you need an experienced and professional team for the job team solutions is ABLE! On the GSA schedule since 2000!

Contact us:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

All rights reserved, copyright , trademark ©

How does GSA advantage work?

1. Find vendors and filter based on project qualifications (example geographic location, business size, reps & certs, etc)

2. Work out a scope or choose a design-build approach with best technical proposal winning the job

3. Set evaluation criteria to meet your goals (ie small business, disadvantaged enterprise, manufacturer, local preference, etc)

4. Post the notification and have all proposals back in within a few days or weeks (subject to technical criteria)

5. Pick your favorite team and get started!

Modular Solutions has successfully completed over $20M in GSA contracts with federal and eligible agencies.

If you need an experienced and professional team for the job team solutions is ABLE! On the GSA schedule since 2000!

Contact us:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

All rights reserved, copyright , trademark ©

Wednesday, August 6, 2014

We Need Space NOW! Year End For Federal Agencies....

It is year end and you have a request for immediate swing space or for a temporary space solution.....don't worry- Modular Solutions, Ltd has a solution!

We have an inventory of modular buildings that can ship immediately based on your project location. For example we have a building that is 17,000 square ft in inventory right now. It is great for general administration, meeting space, swing space, or even for a permanent solution. This is a building that is 100% complete and returning from another client that no longer needs the space.

Team Solutions thoroughly renovates the building so it is fresh and clean & ready to move into in a matter of days. NO NEED TO WAIT - ORDER YOURS TODAY!

We know that every procurement is a priority at year end, our goal is to help you make the schedule, and find a durable and cost-effective design.

Ask about our special GSA pricing and delivery options. Ordering an "in-stock" modular solution is as easy as 1-2-3.

For more information contact our GSA team at:

Modular Solutions, Ltd

Phone (800) 441+-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

BLOG: WWW.MODULARSOLUTIONS.BLOGSPOT.COM

FACEBOOK: www.facebook.com/modularsolutionsltd

all rights reserved copyright, trademark ©

We have an inventory of modular buildings that can ship immediately based on your project location. For example we have a building that is 17,000 square ft in inventory right now. It is great for general administration, meeting space, swing space, or even for a permanent solution. This is a building that is 100% complete and returning from another client that no longer needs the space.

Team Solutions thoroughly renovates the building so it is fresh and clean & ready to move into in a matter of days. NO NEED TO WAIT - ORDER YOURS TODAY!

We know that every procurement is a priority at year end, our goal is to help you make the schedule, and find a durable and cost-effective design.

Ask about our special GSA pricing and delivery options. Ordering an "in-stock" modular solution is as easy as 1-2-3.

For more information contact our GSA team at:

Modular Solutions, Ltd

Phone (800) 441+-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

BLOG: WWW.MODULARSOLUTIONS.BLOGSPOT.COM

FACEBOOK: www.facebook.com/modularsolutionsltd

all rights reserved copyright, trademark ©

Tuesday, August 5, 2014

What Does Life Cycle Mean?

Many architects and designers will work with clients and tell them they have designed a 50 year life cycle or a 100 year life cycle structure. Life cycle is just a combined review of the building structural and design elements by an experienced design professional and an assessment of the approximate useability term of the building. By looking at the type of building materials and building components the architect can help a client decide where to upgrade for a longer life cycle and where the upgraded expense may not pay for its self over the term of the building life cycle.

There are four main components that go into determining the life cycle of new modular construction:

1. The components that are used for the manufacturing

2. The costs and design criteria of the on site construction

3. The operational costs, maintenance, energy costs, repairs

4. The demolitions.......But in the case of modular construction our advantage is that the building can be relocated or reconstructed and is 100% recyclable.

For more information on reducing your carbon footprint and constructing a modular building with an extended life cycle contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionltd.com

facebook: www.facebook.com/modularsolutions

LINKED IN : http://www.linkedin.com/company/modular-solutions-ltd---phoenix

all rights reserved, copyright trademark ©

There are four main components that go into determining the life cycle of new modular construction:

1. The components that are used for the manufacturing

2. The costs and design criteria of the on site construction

3. The operational costs, maintenance, energy costs, repairs

4. The demolitions.......But in the case of modular construction our advantage is that the building can be relocated or reconstructed and is 100% recyclable.

For more information on reducing your carbon footprint and constructing a modular building with an extended life cycle contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionltd.com

facebook: www.facebook.com/modularsolutions

LINKED IN : http://www.linkedin.com/company/modular-solutions-ltd---phoenix

all rights reserved, copyright trademark ©

Friday, August 1, 2014

How Do They Get The Modular Building Ready For Transport?

While this may seem like an answer every manufacturer in the industry would or should answer the same.....you will get a huge variety of quality levels on this matter. A modular building is constructed to drive down the road and be set on the site usually within a few days. As life happens, sometimes modular buildings get constructed and then you will have to wait weeks or months before they can actually be installed on a site. This is a point when how the manufacturer got the building ready for transport can really impact how well your building will survive the storage and waiting experience.

Some tips on what a "well-packaged" modular building should contain:

1. HEAVY DUTY plastic, with a thick mil or even shrink wrap if you know the building will be in storage for a period of time

2. Have a shipping wall at least every 20' to ensure the building shape will hold true and does not torque out of shape

3. Plastic cross straps should be used vertical & horizontal at a minimum of 4' on center to keep plastic secured

3. Use metal straps for cross bracing, wood can also be used but may buckle in harsh climate conditions

4. If you are in a sunny climate use a plastic that has UV protection

Additionally, if you plan on having the building set for a period of time you might want to consider putting piers under the corner and a few locations to "soft-set" the building to maintain the integrity of the the building structure.

For more tips or ideas on this topic contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@Mod-sol.com

website: www.modularsolutionsltd.com

FACEBOOK: www.facebook.com/modularsolutionsltd

all rights reserved copyright, trademark ©

Some tips on what a "well-packaged" modular building should contain:

1. HEAVY DUTY plastic, with a thick mil or even shrink wrap if you know the building will be in storage for a period of time

2. Have a shipping wall at least every 20' to ensure the building shape will hold true and does not torque out of shape

3. Plastic cross straps should be used vertical & horizontal at a minimum of 4' on center to keep plastic secured

3. Use metal straps for cross bracing, wood can also be used but may buckle in harsh climate conditions

4. If you are in a sunny climate use a plastic that has UV protection

Additionally, if you plan on having the building set for a period of time you might want to consider putting piers under the corner and a few locations to "soft-set" the building to maintain the integrity of the the building structure.

For more tips or ideas on this topic contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@Mod-sol.com

website: www.modularsolutionsltd.com

FACEBOOK: www.facebook.com/modularsolutionsltd

all rights reserved copyright, trademark ©

Subscribe to:

Posts (Atom)