Need to know if you need a permit for a modular building?

Want to know the best building practices for your new modular construction design?

Want to know if that "smoking" hot internet deal is really a good buy?

2019 top 10 FAQ's and answers in today's blog on the Modular Solutions website.

https://www.modularsolutionsltd.com/modular-construction-top-10-faq/

www.ModularSolutionsLtd.com

information@mod-sol.com

(800) 441-8577 x 1 (sales)

Showing posts with label design. Show all posts

Showing posts with label design. Show all posts

Monday, January 21, 2019

Wednesday, October 17, 2018

Modern Elegance In Commercial Modular Building Design

The topic of this blog is DON'T SETTLE!

I just published a great article on linkedin follow that link to read more!

We want everyone out there to know you do not have to settle for the OLD modular design standard of wood siding, vinyl gyspum wall board, and VCT tile flooring.

There are so many great custom finishes out there today, for a very feasible fee and this is what Modular Solutions, Ltd preconstruction team specializes in.

Look at stone or marble flooring, consider LED track lighting, ask for a reclaimed wood accent wall, have your LOGO on the storefront entry way, include inviting natural lighting in your design!

All of these design choices are easily accommodate, but not regularly incorporated into modular factory construction. Modular Solutions, Ltd is here to say YES! You can have these great modern and elegant design features incorporated into your new facility and make a statement.

To learn more about a better way to build contact our preconstruction team for a free estimate

Phone: 800-441-8577 x 1 (sales)

email: informaiton@mod-sol.com

WEBSITE: www.ModularSolutionsLtd.com

Friday, January 12, 2018

Modular Mansard Adds Beauty & Dimension

Adding A Modular Building Mansard For Style

Modular buildings have historically been labeled as "boxy" and non dimensional. When we are asked how do you make a modular have style and character, we often recommend a modular building mansard. If you do not know what a mansard is, it is a dimensional overhang made from various materials that add roof height, and dimensional overhang on all four sides of the building.

In the modular industry a majority of the mansards are constructed with steel or stucco, but we have also used cedar, concrete tiles, copper, and more. The great thing is you can play with the angle of the design to have a varied final appearance.

READ MORE in our daily blog on our website, or contact our sales representative to learn more about how a mansard can create that special design element you have been wanting to see in a modular building.

Call us: 800-441-8577 x 1 Sales

Monday, March 6, 2017

Modular Building Windows, What Are My Choices

What Type Of Windows Can We Use In our Modular Building?

Commercial modular buildings are constructed to the IBC code, the same code as any traditional site contractor will use. The goal is to design a building that allows natural light, but that also has energy efficiency built into the modular building design.

What to look for: The National Fenestration Rating Council offers five areas to consider when selecting windows for your new modular building.

- U-Factor determines how well a window prevents heat from escaping. U-Factor ratings generally fall between 0.20 and 1.20 the lower number is best at keeping heat in. This is a great consideration for a modular church building.

- Solar Heat Gain Coefficient (SHGC) reflects how well a product will blocks heat from the sun. SHGC is expressed as a number between 0 and 1, a lower SHGC indicating a product that is better at blocking unwanted heat gain. This is important when constructing a modular hospital or clinical facility.

- Visible Transmittance (VT) indicates how much light comes through the window. VT is expressed as a number between 0 and 1 the higher the VT number the higher the potential for daylighting. This is important in modular educational spaces.

- Air Leakage (AL) measures how much outside air comes into your new modular building. AL rates typically fall in a range between 0.1 and 0.3 the lower AL is better at keeping air out. This should be considered in modular hospitality projects.

- Condensation Resistance (CR) measures how well a window resists the formation of condensation. CR will show a number between 1 and 100 with a higher CR indicating a product better able to resist condensation. Federal modular building projects often look at this consideration

- Low E Windows will cost about 10% or 15% more than standard windows, but will supposedly reduce energy loss by as much as 50%.

- There are also lots of options for coatings, screens, shutters, frame materials, and opening operation.

- For more information contact our design team & we can help you make informed decisions on the best value for your new modular building.

- Modular Solutions, Ltd

- Phone: 800-441-8577 x 1 (Sales)

- Email: Information@Mod-sol.com

- website: www.modularsolutionsltd.com

- facebook: www.facebook.com/modularsolutionsltd

- You Tube: www.youtube.com/user/Modularsolutionsltd

Tuesday, October 25, 2016

Need An IT Room In Your New Modular Building, Read These Five Great Tips

How To Design Your IT Room, Five Great Tips

Almost every new modular building being constructed for traditional office space use has an IT room included. Over the years we have seen the evolution of this crucial space. Some manufacturers would just build a closet causing overheating, some manufacturers put in a large AC drop causing the AC units to freeze up or over cycle.

When you are depending on technology to run so many aspects of your business, how much would it cost you if your communication or data systems are down?

Here are a few tips to look at when you are designing your new modular building.

1. Size the room based on the amount of equipment you will have in your facility. Over sizing or undersizing a room can cause issues with the operations of your system.

2. Do not use the space for "storage" of other things. Frequently we will see designated IT rooms become storage for office and cleaning supplies or spare parts. Keep the IT room clean and free of clutter. If you need storage, design in additional storage rooms.

3. Static resistant flooring is the recommendation.

Use wood, laminate, tile, or some other easy maintenance non-static material for the floor covering in the IT room.

4. If you are not using a professional rack in the IT room, then make sure your include a backer board that is coated with a fire restive material. Some clients will even make the entire room a one hour fire rated room.

5. We recommend IT rooms have a mini-split system with a ductless cooling unit dedicated to that room.

In the event there are thermostat wars in the office spaces your IT room will remain cool and consistent based on the temperature setting you and your team select. Large data rooms can exhaust through the floor or crawl space if you design your facility using a professional team.

In the event there are thermostat wars in the office spaces your IT room will remain cool and consistent based on the temperature setting you and your team select. Large data rooms can exhaust through the floor or crawl space if you design your facility using a professional team.

For more great tips and ideas about how to build a better modular building contact our team for a free consultation:

Phone: 800-441-8577 x 1 (sales)

Email: Information@mod-sol.com

website: www.modularsolutionsltd.com

Monday, April 25, 2016

Commercial Modular Buildings - Five Well Kept Secrets

Five Top Secrets The Modular Industry Does Not Always Share

1. MYTH: Commercial modular buildings only come in wood, cement panel, steel, or stucco finish.

TRUTH: Commercial modular buildings have unlimited finish options. Blending in with a community is often the desired outcome. Choose a company with a professional design team to help you create the perfect design solution.

3. MYTH: Building on a slope is not possible with a commercial modular building. TRUTH: Commercial modular buildings have to be placed where there is space and sometimes that is between a rock & a hard spot. With the use of creative and innovative foundation systems we can place a modular building in almost any location. Cranes, railsets, and special installation tools help commercial modular buildings fit on those unique installation locations.

4: MYTH: You don't need an architect if you choose modular construction: TRUTH: Modular buildings, especially custom commercial modular buildings require the experience and code review to keep your building safe and architecturally interesting. Whether you choose a private architect or a modular building company like Modular Solutions, Ltd that has N.C.A.R.B architects on staff make sure you bring someone on board that has the knowledge of prefabrication, and structural design.

5: MYTH: Modular buildings have to be rectangular boxes and straight shapes of 12' x 60' sections. TRUTH: At Modular Solutions we have built "H" or "T" or "L" shapes, but also circular walls and hogan shaped walls. Our goal is to give clients what they want & make sure it is built to the same construction methods a traditional site built structure is constructed to. Why Settle?

For more information contact our team at Modular Solutions, Ltd

Phone: (800) 441-8577 x 1 (Sales)

Email: information@mod-sol.cominformation@mod-sol.com

Monday, March 23, 2015

Case Study, ADA Egress For CES Member

There are many locations throughout New Mexico that have ramps and stairs that were built from wood and the signs of aging are quite apparent. If a school district or non-profit organization has a building that does not meet current ADA requirements, or that has unsafe egress into a facility they face the challenge of losing funding or not qualifying for grants.

Modular Solutions, Ltd helped out a CES Member become compliant by providing new ADA ramps & decks.

With our in-house design team we were able to asses the requirements, and make sure the new egress for the facility was compliant.

There are many ways to design handicap access into a facility, but if your team does not design it properly it can be very expensive or it will fail inspection.

Call our team for a free inspection and proposal on getting compliant.

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutionsltd

Modular Solutions, Ltd helped out a CES Member become compliant by providing new ADA ramps & decks.

With our in-house design team we were able to asses the requirements, and make sure the new egress for the facility was compliant.

There are many ways to design handicap access into a facility, but if your team does not design it properly it can be very expensive or it will fail inspection.

Call our team for a free inspection and proposal on getting compliant.

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutionsltd

Wednesday, October 29, 2014

Cost Effective Designs To Get A Higher Ceiling

One question we frequently hear is how do I get a higher ceiling in my modular building? Some uses like worship facilities, or multipurpose rooms, or physical activity spaces need a higher ceiling to effectively service the space goals.

The Challenge:

When a modular building gets over 15' or 16' high in most states, the transport gets extremely cost prohibitive. This reduces the cost savings that are realized by choosing modular construction. Our clients have come to us with this challenge and Modular Solutions, Ltd has come up with some cost-effective design solutions that help keep the transport fees affordable, and help keep the overall budget of the project in line with original cost projections.

1. Telescoping Roof: A telescoping roof system is one that is raised when it arrives on site allowing the building sections to transport down the road for the lower delivery costs, and still gain the additional ceiling height once the building is installed on site.

2. Hinged Roof: A hinged roof system is similar to a telescoping roof. This is common for smaller structures that are only two or three sections to obtain a nice high pitch in snow country.

3. Site Installed Stacks: Installing sections on top of each other with proper foundation and crane rigging on site saves time and money by allowing high roof sections to be set on each other with proper design & engineering details.

4. Clearspan Beams: Open up the ceiling and use a decorative steel duct system so it can be exposed allowing the roof beams and duct work to be open, like in a warehouse or restaurant setting. This picks up 1-2 additional feet in the ceiling height.

These are just a few of the creative and innovative solutions Modular Solutions, Ltd has developed for clients that have the need for additional ceiling height in a modular building structure.

For more information regarding how to design innovative space solutions contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1 (sales)

Email: Information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved copyright, trademark

The Challenge:

When a modular building gets over 15' or 16' high in most states, the transport gets extremely cost prohibitive. This reduces the cost savings that are realized by choosing modular construction. Our clients have come to us with this challenge and Modular Solutions, Ltd has come up with some cost-effective design solutions that help keep the transport fees affordable, and help keep the overall budget of the project in line with original cost projections.

1. Telescoping Roof: A telescoping roof system is one that is raised when it arrives on site allowing the building sections to transport down the road for the lower delivery costs, and still gain the additional ceiling height once the building is installed on site.

2. Hinged Roof: A hinged roof system is similar to a telescoping roof. This is common for smaller structures that are only two or three sections to obtain a nice high pitch in snow country.

3. Site Installed Stacks: Installing sections on top of each other with proper foundation and crane rigging on site saves time and money by allowing high roof sections to be set on each other with proper design & engineering details.

4. Clearspan Beams: Open up the ceiling and use a decorative steel duct system so it can be exposed allowing the roof beams and duct work to be open, like in a warehouse or restaurant setting. This picks up 1-2 additional feet in the ceiling height.

These are just a few of the creative and innovative solutions Modular Solutions, Ltd has developed for clients that have the need for additional ceiling height in a modular building structure.

For more information regarding how to design innovative space solutions contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1 (sales)

Email: Information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved copyright, trademark

Thursday, October 23, 2014

Fire Safety, What is NFPA 285?

Modular Buildings and Site Built Structures, should be built in accordance with safety in mind!

Understanding What is NFPA 285

In 1998, the National Fire Protection Association (NFPA) established the NFPA 285 “Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Non-Load-Bearing Wall Assemblies Containing Combustible Components.” NFPA 285 provides a determination of vertical fire performance for exterior wall assemblies, which is verified by actual testing. It is intended to help builders reduce the potential for upward spread of fire through wall.

The requirement for a weather-resistive barrier is as follows:

WRB (Weather-Resistive Barrier) Code Requirement: 1403.5 Vertical and Lateral Flame Propagation – Exterior walls on buildings of Type I, II, III, or IV construction that are greater than 40 feet (12.192m) in height above grade plane, and contain a combustible water-resistive barrier, shall be tested in accordance with, and comply with the acceptance criteria of NFPA 285.

For this reason, Modular Solutions, Ltd partners with companies such as DuPont™ Tyvek® air and water barriers designed for commercial construction because they have been tested and shown to meet NFPA 285, the National Fire Protection Association fire performance standard for vertical wall assemblies.

For more information on fire safety in multistory modular construction consult our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1 (sales)

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutionsltd

all rights reserved, copyright trademark ©

Understanding What is NFPA 285

In 1998, the National Fire Protection Association (NFPA) established the NFPA 285 “Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Non-Load-Bearing Wall Assemblies Containing Combustible Components.” NFPA 285 provides a determination of vertical fire performance for exterior wall assemblies, which is verified by actual testing. It is intended to help builders reduce the potential for upward spread of fire through wall.

The requirement for a weather-resistive barrier is as follows:

WRB (Weather-Resistive Barrier) Code Requirement: 1403.5 Vertical and Lateral Flame Propagation – Exterior walls on buildings of Type I, II, III, or IV construction that are greater than 40 feet (12.192m) in height above grade plane, and contain a combustible water-resistive barrier, shall be tested in accordance with, and comply with the acceptance criteria of NFPA 285.

For this reason, Modular Solutions, Ltd partners with companies such as DuPont™ Tyvek® air and water barriers designed for commercial construction because they have been tested and shown to meet NFPA 285, the National Fire Protection Association fire performance standard for vertical wall assemblies.

For more information on fire safety in multistory modular construction consult our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1 (sales)

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutionsltd

all rights reserved, copyright trademark ©

Monday, September 22, 2014

Indoor Air Quality, What Is That?

One phrase that has been seen more in the modular building industry lately is "indoor Air Quality". What does that really mean?

Indoor air quality (IAQ) simply refers to the air quality within modular and traditional constructed buildings and structures. IAQ usually relates to the health and comfort of building occupants. IAQ can be affected by gases (including carbon monoxide, radon, volatile organic compounds), particulates, microbial contaminants (mold, bacteria), or any mass or energy stressor that can induce adverse health conditions. In most cases buildings being utilized for classroom or office use can be brought up to current standards by updating fresh air standards. Some occupants can be sensitive to the gases in a building (traditional or modular), and need special corrections.

When a project is LEED the category this usually falls under is Indoor Environmental Quality (IEQ). This is only one of the categories, that LEED uses as a standard to provide comfort, well-being, and productivity of the building occupants. The LEED IEQ category helps address design and construction guidelines pertaining to: indoor air quality (IAQ), thermal quality, and lighting quality.

Proper building ventilation, fresh air, windows, natural & electric lighting, VOC or gas emissions, all fall under the environmental conditions inside a modular or traditional structure.

For more information on proper indoor air quality levels and design contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright trademark 2014©

Indoor air quality (IAQ) simply refers to the air quality within modular and traditional constructed buildings and structures. IAQ usually relates to the health and comfort of building occupants. IAQ can be affected by gases (including carbon monoxide, radon, volatile organic compounds), particulates, microbial contaminants (mold, bacteria), or any mass or energy stressor that can induce adverse health conditions. In most cases buildings being utilized for classroom or office use can be brought up to current standards by updating fresh air standards. Some occupants can be sensitive to the gases in a building (traditional or modular), and need special corrections.

When a project is LEED the category this usually falls under is Indoor Environmental Quality (IEQ). This is only one of the categories, that LEED uses as a standard to provide comfort, well-being, and productivity of the building occupants. The LEED IEQ category helps address design and construction guidelines pertaining to: indoor air quality (IAQ), thermal quality, and lighting quality.

Proper building ventilation, fresh air, windows, natural & electric lighting, VOC or gas emissions, all fall under the environmental conditions inside a modular or traditional structure.

For more information on proper indoor air quality levels and design contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright trademark 2014©

Friday, August 15, 2014

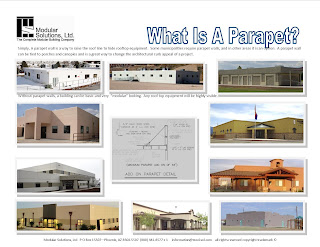

What Is A Parapet Wall?

When modular buildings are transported down the road they have to be within standard shipping heights allowed by the Department of Transportation. Additionally, sometimes the route to the project site has low overhead traffic lights or low bridges. Before any modular building goes down the road, the project manager will check the route to the site and see what type of height restrictions might be encountered, and if there is an alternative route. Modular companies that have a preconstruction team, will investigate these items during the design phase to avoid project surprises and expense.

What does all of this information have to do with a parapet wall? When clients want a higher profile modular building or have to hide mechanical roof top equipment they will add a parapet wall to raise the roof line and add architectural interest to the visual aspects of the modular building.

What is a parapet wall? The parapet wall can either be built on site, or in the plant, and is an addition that goes above he exterior perimeter walls. A parapet wall can be basic and squared off or a parapet wall can have fun architectural shapes. Parapet wall built in the plant will usually be 3' to 4' high so that the parapet walls can ship and install easily. Taller parapet walls are common but require additional design engineering.

For more information contact our team:

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark ©

What does all of this information have to do with a parapet wall? When clients want a higher profile modular building or have to hide mechanical roof top equipment they will add a parapet wall to raise the roof line and add architectural interest to the visual aspects of the modular building.

What is a parapet wall? The parapet wall can either be built on site, or in the plant, and is an addition that goes above he exterior perimeter walls. A parapet wall can be basic and squared off or a parapet wall can have fun architectural shapes. Parapet wall built in the plant will usually be 3' to 4' high so that the parapet walls can ship and install easily. Taller parapet walls are common but require additional design engineering.

For more information contact our team:

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark ©

Friday, July 18, 2014

Show Me Some Fun Projects!

When we meet with clients we are often asked what is possible with modular construction? The answer.....ANYTHING! When you set down in the design stages and have a team create innovative design solutions you are able to make the perfect space solution!

I have had readers ask me to share some of our fun and memorable projects that have been done over the years. In my time in the industry (mid 80's) until now we have seen modular buildings go from basic boxes on wheels, to elaborate very dimensional projects. Over the next week I will highlight a few fun projects that were unique and that really show the flexibility of prefabricated construction. Until then have a great weekend!

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright trademark ©

I have had readers ask me to share some of our fun and memorable projects that have been done over the years. In my time in the industry (mid 80's) until now we have seen modular buildings go from basic boxes on wheels, to elaborate very dimensional projects. Over the next week I will highlight a few fun projects that were unique and that really show the flexibility of prefabricated construction. Until then have a great weekend!

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright trademark ©

Tuesday, July 15, 2014

What Do I Do If We Have Bad Soil Conditions?

We are frequently asked by clients on a tight budget, "why do we want to spend money on testing the soil, aren't modular buildings made to move with the ground?"

I guess to answer that question you have to ask a few questions.

1. What are your goals for the modular building - temporary or permanent use

2. Has there been any construction in this area before to look for signs of bad soil conditions with other structures

3. Can we do a little test dig where you want this to go & take a look

Soils testing is performed by an engineering company that specializes in geotechnical surveys. The reason you do a geotechnical survey is to find out what kind of ground conditions the modular building and the foundation will be setting on. If you have soil that is expansive or that moves you will want to excavate out or even bring in new soil to mix with the bad soil so your building does not settle or your foundation does not fail. Have you ever watched those sink hole videos on the internet? Not a good example of solid soil conditions.

Modular buildings are designed to have some give/take room, which is why many modular building dealers will set a modular building on piers & just readjust the piers as a building shifts or moves. While you may see this in the industry for short term temporary installations it is not recommended on long term or permanent installations. Piers that adjust do not "fix" bad soil conditions and if not addressed by an engineering professional you may be at risk.

Many states have regulations regarding soil condition reports and enforce those regulations. It is always best to work with a company that has experience in grading and in soil conditions reporting so that you can make an educated and informed decision.

For more details on soil conditions & modular building installations contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

website: www.modularsolutionsltd.com

email: Information@mod-sol.com

all rights reserved © copyright & trademark

I guess to answer that question you have to ask a few questions.

1. What are your goals for the modular building - temporary or permanent use

2. Has there been any construction in this area before to look for signs of bad soil conditions with other structures

3. Can we do a little test dig where you want this to go & take a look

Soils testing is performed by an engineering company that specializes in geotechnical surveys. The reason you do a geotechnical survey is to find out what kind of ground conditions the modular building and the foundation will be setting on. If you have soil that is expansive or that moves you will want to excavate out or even bring in new soil to mix with the bad soil so your building does not settle or your foundation does not fail. Have you ever watched those sink hole videos on the internet? Not a good example of solid soil conditions.

Modular buildings are designed to have some give/take room, which is why many modular building dealers will set a modular building on piers & just readjust the piers as a building shifts or moves. While you may see this in the industry for short term temporary installations it is not recommended on long term or permanent installations. Piers that adjust do not "fix" bad soil conditions and if not addressed by an engineering professional you may be at risk.

Many states have regulations regarding soil condition reports and enforce those regulations. It is always best to work with a company that has experience in grading and in soil conditions reporting so that you can make an educated and informed decision.

For more details on soil conditions & modular building installations contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

website: www.modularsolutionsltd.com

email: Information@mod-sol.com

all rights reserved © copyright & trademark

Friday, June 20, 2014

Why Are There Different "A" Occupancies In Modular Buildings?

We have clients that are churches or non-profit organizations that just need lots of wide open space but don't understand why there are so many types of "A" occupancies. While the total size of the building is a huge factor the basic uses are common practice.

Here is a break out of the basic uses:

A-1: Fixed seating such as theater or concert halls

A-2: Food & Drink Consumption such as restaurant or banquet halls

A-3: Intended for Worship, amusement or recreation such as churches, community halls, art galleries, museums, libraries

A-4: Indoor sporting events such as ice skating rinks, arenas, tennis courts

A-5: Outdoor Activity Viewing such as grandstands or amusement parks

If you have less than 50 occupants it can even be considered "B" occupancy.

The code is very flexible and is best left to the architectural team to help you select the best design & value for your space goals. Contact our team for more information.

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright, trademark ©

Here is a break out of the basic uses:

A-1: Fixed seating such as theater or concert halls

A-2: Food & Drink Consumption such as restaurant or banquet halls

A-3: Intended for Worship, amusement or recreation such as churches, community halls, art galleries, museums, libraries

A-4: Indoor sporting events such as ice skating rinks, arenas, tennis courts

A-5: Outdoor Activity Viewing such as grandstands or amusement parks

If you have less than 50 occupants it can even be considered "B" occupancy.

The code is very flexible and is best left to the architectural team to help you select the best design & value for your space goals. Contact our team for more information.

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright, trademark ©

Wednesday, June 18, 2014

Sizzling Summer Heat, Ways To Save On Your Energy Bill (6) Tips

When summer hits full force utility bills soar sky high as mechanical units run non-stop in certain parts of the country. We are asked what are some tips to bring down the cost of operating expense during the summer heat.

1. Change your filters, Will help units run more efficiently

2. Check duct work for leaks or possible repairs

3. Strategically plant landscape, to help with shade & summer heat penetration

4. Cover windows with shade screens and reflective coatings

5. More expensive, but helpful reflective coating or white roof

6. higher SEER HVAC units operate more efficiently, if you have old units maybe time for a replacement and NOW, there are tax rebates for this type of upgrade

For more tips contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@Mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright, trademark ©

1. Change your filters, Will help units run more efficiently

2. Check duct work for leaks or possible repairs

3. Strategically plant landscape, to help with shade & summer heat penetration

4. Cover windows with shade screens and reflective coatings

5. More expensive, but helpful reflective coating or white roof

6. higher SEER HVAC units operate more efficiently, if you have old units maybe time for a replacement and NOW, there are tax rebates for this type of upgrade

For more tips contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@Mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright, trademark ©

Wednesday, June 11, 2014

Metal Roof Or Shingle Roof For My Modular Building?

We are frequently asked by clients if they should choose a metal or shingle roof covering there are pros & cons of both types. Consider this as you weigh your decision:

Shingle Roof Advantages:

1. Readily Available

2. Cost-Effective

3. Easy to Replace or Repair

4. Variety Of Color Choices

5. Can Ship Complete From Factory

6. Easy Penetration Seal

Shingle Roof Disadvantages:

1. Damages More Easily In High Wind Locations

2. Shorter Life Cycle Than Metal, about 1/3rd the life span

3. More Maintenance & Visual Inspections Required

Metal Roof Advantages:

1. Steel Roof Life Cycle Measured At 50+ Years By Roofing Industry

2. Steel Roof Very Low Maintenance Cost

3. Steel Roof "White" Covering, Is Considered Energy Wise For Reflective Value

4. Lightweight & Versatile Panel Shapes

5. Fire Resistant Material & Some Insurance Reductions If Applicable

Metal Roof Disadvantages:

1. More Expensive Initially Than Shingle Roof

2. Penetrations Can Sometimes Lead To Leaks If Not Sealed & Maintained

3. More Expensive To Replace Or Repair

Both systems are highly utilized in the modular industry. Our preconstruction team has cut sheets and comparisons on file for you to review & make an educated & informed decision. There are lots of roof covering choices, we are just showing a comparison between two highly common ones selected in the modular industry. For more details contact our team at Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

Shingle Roof Advantages:

1. Readily Available

2. Cost-Effective

3. Easy to Replace or Repair

4. Variety Of Color Choices

5. Can Ship Complete From Factory

6. Easy Penetration Seal

Shingle Roof Disadvantages:

1. Damages More Easily In High Wind Locations

2. Shorter Life Cycle Than Metal, about 1/3rd the life span

3. More Maintenance & Visual Inspections Required

Metal Roof Advantages:

1. Steel Roof Life Cycle Measured At 50+ Years By Roofing Industry

2. Steel Roof Very Low Maintenance Cost

3. Steel Roof "White" Covering, Is Considered Energy Wise For Reflective Value

4. Lightweight & Versatile Panel Shapes

5. Fire Resistant Material & Some Insurance Reductions If Applicable

Metal Roof Disadvantages:

1. More Expensive Initially Than Shingle Roof

2. Penetrations Can Sometimes Lead To Leaks If Not Sealed & Maintained

3. More Expensive To Replace Or Repair

Both systems are highly utilized in the modular industry. Our preconstruction team has cut sheets and comparisons on file for you to review & make an educated & informed decision. There are lots of roof covering choices, we are just showing a comparison between two highly common ones selected in the modular industry. For more details contact our team at Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

Friday, May 16, 2014

How Large Should I Make My Offices In My Modular Building?

A modular building that is used for office space has typical sizes if you lease or purchase "stock" equipment. Most buildings that are "inventory" equipment include offices that are approximately 12' x 10'. Building codes says you need to use 100 square ft per person as a head count, the question is what is the office function. Here are a few rule of thumb examples that we have used for architectural space planning over the years. Every case is unique, but rule of thumb is always a good place to start.

1. Support staff or part time staff can usually get away with 80 - 100 sq ft office spaces or share an office with 150 square ft every two people. If you make the space too small you may lose productivity with disorganization.

1a. If you have a built in work desk for multiple employees, make sure they each have at least 3' wide for work space.

2. Full time employees with a desk and a computer station & files typically need 100-150 square ft for comfortable flow

3. Managers or Directors Will usually add a small conference table or store lots of referral material, so their offices are usually 150 square ft - 250 square ft

4. Executives have earned the right for space, so typically executive office have windows, corner office, exterior doors, their own restroom, and this will be 400-500 square ft.

Another good gauge is what industry are you in? For example medical offices will be larger than telemarketing offices or sales reps that are in the filed most of the day.

To learn more about proper space planning consult our team at Modular Solutions, Ltd

Phone: 800-441-8577

email: information@mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutionsltd

1. Support staff or part time staff can usually get away with 80 - 100 sq ft office spaces or share an office with 150 square ft every two people. If you make the space too small you may lose productivity with disorganization.

1a. If you have a built in work desk for multiple employees, make sure they each have at least 3' wide for work space.

2. Full time employees with a desk and a computer station & files typically need 100-150 square ft for comfortable flow

3. Managers or Directors Will usually add a small conference table or store lots of referral material, so their offices are usually 150 square ft - 250 square ft

4. Executives have earned the right for space, so typically executive office have windows, corner office, exterior doors, their own restroom, and this will be 400-500 square ft.

Another good gauge is what industry are you in? For example medical offices will be larger than telemarketing offices or sales reps that are in the filed most of the day.

To learn more about proper space planning consult our team at Modular Solutions, Ltd

Phone: 800-441-8577

email: information@mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutionsltd

Wednesday, May 14, 2014

Can A Modular Building Have ADA Doors?

Commercial modular buildings actually require all doors to be a minimum of 36" and ADA accessible. A door needs to be large enough to have a wheelchair egress through the door. There are many types of doors available for versatile appearance. Doors can also be larger than 36" for oversize wheel chairs and scooters. Facilities such as clinics and wellness centers often have 42" or 48" doors.

When looking at ADA design, you will also want to look at the angle of hallways and the width of hallways. When you are dealing with scooters or oversize wheelchairs more space and direct angles are key to making a modular building more ADA friendly.

For more tips and ideas on making an ADA modular building contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutionsltd

When looking at ADA design, you will also want to look at the angle of hallways and the width of hallways. When you are dealing with scooters or oversize wheelchairs more space and direct angles are key to making a modular building more ADA friendly.

For more tips and ideas on making an ADA modular building contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutionsltd

Monday, May 12, 2014

How Do I Make My Modular Building Workplace Safer? (5) great tips

Whether you are in a site built or modular building the safety of employees is a great concern. We have some great general tips that will help encourage employees that your organization is doing everything they can to offer a safer work place environment no matter what the external existing conditions might be.

1. Trim back all hedges and landscape. If there are no hiding places employees can get to vehicles safely and know they are visible.

2. Have great exterior lighting. Whether that is parking lot lighting on a pole, or wall sconces mounted to the modular building, light will help divert criminal activity to a different location.

3. Fences and gates should have lighting. If possible have an automatic gate system. This way an employee does not have to exit their vehicle after leaving the modular building.

4. Employees in remote areas can arm their modular building with a security alarm feature. This can be set off in emergencies to divert criminal activity, making your employees feel more confident.

5. Open the floor to suggestions, have a wall box on your modular building or in staff meeting to allow staff to make suggestions for a safer workplace environment.

If you have a new modular building this can be incorporated into the design, if you have an existing modular building the modular building or site can be retrofitted to accommodate.

For more information on designing a safer modular building, contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

blog: www.modularsolutions.blogspot.com

facebook: www.facebook.com/modularsolutionsltd

Youtube: http://www.youtube.com/user/modularsolutionsltd

all rights reserved, copyright, trademark ©

1. Trim back all hedges and landscape. If there are no hiding places employees can get to vehicles safely and know they are visible.

2. Have great exterior lighting. Whether that is parking lot lighting on a pole, or wall sconces mounted to the modular building, light will help divert criminal activity to a different location.

3. Fences and gates should have lighting. If possible have an automatic gate system. This way an employee does not have to exit their vehicle after leaving the modular building.

4. Employees in remote areas can arm their modular building with a security alarm feature. This can be set off in emergencies to divert criminal activity, making your employees feel more confident.

5. Open the floor to suggestions, have a wall box on your modular building or in staff meeting to allow staff to make suggestions for a safer workplace environment.

If you have a new modular building this can be incorporated into the design, if you have an existing modular building the modular building or site can be retrofitted to accommodate.

For more information on designing a safer modular building, contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

blog: www.modularsolutions.blogspot.com

facebook: www.facebook.com/modularsolutionsltd

Youtube: http://www.youtube.com/user/modularsolutionsltd

all rights reserved, copyright, trademark ©

Tuesday, May 6, 2014

Can I Get Ceramic Tile Or Wood Floors In My Modular Building?

Many modular factories try to keep costs lower by offering limited selections of colors and finishes to their clients. While this way of building offers a little cost savings, most clients feel it is better to get what you really want when you are getting a custom designed and build modular building. We have been asked if modular buildings can have ceramic tile walls or floor covering. In most cases the answer is YES. The fun part is deciding which finish you want, and how much you want to spend in your budget. The choices are unlimited. The key to having a successful installation of wood flooring or ceramic tiles is in proper installation.

(5) great tips:

1. Choose a heavier floor decking the industry standard is 5/8" thick, and we suggest 3/4" or 1 1/8"

2. Use an underlayment such as wonder board or equal that lets the movement transfer as required

3. Trim and transition strips can be attractive and blend in, or basic know you have choices

4. Have your tile professionally cleaned and sealed, depending on what type you get (natural stone better not to seal)

5. Use proper cleaning instructions for water/steam/cleaning to ensure you do not over saturate your new flooring

For more great tips contact our team at Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@Mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutonsltd

youtube: http://www.youtube.com/user/modularsolutionsltd

all rights reserved, copyright, trademark ©

(5) great tips:

1. Choose a heavier floor decking the industry standard is 5/8" thick, and we suggest 3/4" or 1 1/8"

2. Use an underlayment such as wonder board or equal that lets the movement transfer as required

3. Trim and transition strips can be attractive and blend in, or basic know you have choices

4. Have your tile professionally cleaned and sealed, depending on what type you get (natural stone better not to seal)

5. Use proper cleaning instructions for water/steam/cleaning to ensure you do not over saturate your new flooring

For more great tips contact our team at Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@Mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutonsltd

youtube: http://www.youtube.com/user/modularsolutionsltd

all rights reserved, copyright, trademark ©

Subscribe to:

Posts (Atom)