Our goal in 2015 will be to build solutions for space challenges! Our team has already had some great schedule and technical challenges put before us for 2015! If you think you have a project that seems impossible, we are here to help develop a solution! No location, or schedule, or design will be too crazy for our team to meet & help get it done!

For more information on Modular Solutions, Ltd contact our team:

email: information@mod-sol.com

website: www.modularsolutionsltd.com

Phone: 800-441-8577 x 1 (Sales)

all rights reserved copyright, trademark ©

Tuesday, December 30, 2014

Tuesday, December 16, 2014

Light Up Your Commercial Modular Building

This time of year there are fun places to go & look at lights, and commercial buildings are no exception

A few of my favorites are in today's blog.

So if you are thinking about how to make your commercial modular building a little brighter this season, just get the glitter & the lights out & get creative!

For more information contact our team at:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright trademark 2014©

A few of my favorites are in today's blog.

So if you are thinking about how to make your commercial modular building a little brighter this season, just get the glitter & the lights out & get creative!

For more information contact our team at:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright trademark 2014©

Monday, December 8, 2014

Purchasing Cooperative of America Awards Five Year Contract To Modular Solutions, Ltd

What is Cooperative Purchasing?

Cooperative purchasing is a way for small and remote (school districts, non-profits, local, county, state municipalities) to buy products and or services from a vendor that is prequalified, and that will offer the best value.

Purchasing Cooperative Of America (PCA) is a purchasing cooperative with contracts available for Public, Private and Charter Schools, Municipalities, States, Federal and Other Government Agencies, State and Private Colleges and Universities, and Non-Profit, Religious and Charitable Organizations . PCA members in all 50 States and the U.S. territories.

PCA is administered by Region III Education Service Center in Victoria, Texas, a Texas state agency. The State Agency connection is vitally important when members are spending federal funds. Where federal dollars are spent or commingled, the purchasing cooperative used must be administered by a State agency with the [cooperative] contracts awarded and held by that agency. Region III ESC awards and holds PCA contracts and administers the PCA cooperative purchasing program. Members benefit because PCA understands the needs of small as well as large public purchasing departments and their limits on time, personnel and expertise. The PCA cooperative program combines the benefits of specialty, local, and regional co-ops into a national program appealing to national companies with the value of industry best practice.

Modular Solutions, Ltd was awarded the PCA contract for best value, prior experience, flexible design, and superior qualifications.

For more information on cooperative purchasing or Modular Solutions, Ltd contract contact your representative:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

Cooperative purchasing is a way for small and remote (school districts, non-profits, local, county, state municipalities) to buy products and or services from a vendor that is prequalified, and that will offer the best value.

Purchasing Cooperative Of America (PCA) is a purchasing cooperative with contracts available for Public, Private and Charter Schools, Municipalities, States, Federal and Other Government Agencies, State and Private Colleges and Universities, and Non-Profit, Religious and Charitable Organizations . PCA members in all 50 States and the U.S. territories.

PCA is administered by Region III Education Service Center in Victoria, Texas, a Texas state agency. The State Agency connection is vitally important when members are spending federal funds. Where federal dollars are spent or commingled, the purchasing cooperative used must be administered by a State agency with the [cooperative] contracts awarded and held by that agency. Region III ESC awards and holds PCA contracts and administers the PCA cooperative purchasing program. Members benefit because PCA understands the needs of small as well as large public purchasing departments and their limits on time, personnel and expertise. The PCA cooperative program combines the benefits of specialty, local, and regional co-ops into a national program appealing to national companies with the value of industry best practice.

Modular Solutions, Ltd was awarded the PCA contract for best value, prior experience, flexible design, and superior qualifications.

For more information on cooperative purchasing or Modular Solutions, Ltd contract contact your representative:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

Tuesday, November 25, 2014

Happy Thanksgiving From Modular Solutions, Ltd

Thank you to everyone that has supported Modular Solutions, Ltd this year. We are looking into the new year with a healthy backlog of production orders, and some really fun projects.

We are grateful that our family at Modular Solutions, Ltd has grown, and that we have built a great team!

Contact us:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

We are grateful that our family at Modular Solutions, Ltd has grown, and that we have built a great team!

Contact us:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

Wednesday, November 19, 2014

Prefabricated Prison Solutions

There is a growing population in the USA that is almost impossible to keep up with, and that is prison inmates. With a tough economy, and rampant substance abuse small and petty crimes are overloading the prison system. Overcrowding is a huge problem that leads to additional challenges within the prison system. It takes on average over 24 months to design a prison addition and deal with the complexities of an addition or a new facility. Most states have adopted prefabricated prison methods. This is accomplished in many different ways.

* Concrete Cells

* Steel Cells

* Modular Construction All Steel

The fabrication time for modular prison units has had prison facilities across the USA ready to occupy in months instead of years. There are many additional design features are incorporated into a prison or jail facility, depending on the security level.

If you are facing tough overcrowding prison challenges, then contact our team of experts for a design-build solution. We will take you walk you through commissioning, and design phase through full warranty. No project is to remote or too challenging.

Contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@Mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright, trademark ©

* Concrete Cells

* Steel Cells

* Modular Construction All Steel

The fabrication time for modular prison units has had prison facilities across the USA ready to occupy in months instead of years. There are many additional design features are incorporated into a prison or jail facility, depending on the security level.

If you are facing tough overcrowding prison challenges, then contact our team of experts for a design-build solution. We will take you walk you through commissioning, and design phase through full warranty. No project is to remote or too challenging.

Contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@Mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright, trademark ©

Friday, November 14, 2014

Cabinets-Cabinets, What Type Should I Put In My Modular Building?

At Modular Solutions,Ltd we are frequently involved in the early planning stages of an addition with our clients. One question we hear frequently is what type of cabinet should we put in our facility. The answer to that is driven by budget, functionality, use, personal taste, and schedule.

When we work with our clients during the commissioning or preconstruction phase we talk through a variety of questions to help them decide what is the best fit for their long and short term goals, and what is the best solution to meet cabinet and storage needs.

(5) Most Common Cabinet Types:

1. PREFABRICATED: This term is commonly used when there is a thin paper veneer over a compressed wood product and this is the face of your cabinets. For a really tight budget, very compressed schedule, or a low use area this type of cabinet will fit the use.

2. ALL WOOD FACED DOORS: This type of cabinet is attractive, and durable great for offices or standard daily use. They can be found "in-stock" or can be custom order depending on selection. The pricing is moderate but overall a good investment.

3. LAMINATE CABINETS: Laminate cabinets are commonly found in medical labs or doctors offices. They are washable and non-porous so they make a great "clean" option to store medical supplies. The cost is on the higher end, but when purchased from a quality manufacturer they will endure. They are usually custom order so allow a little more time in the schedule for this type of cabinet.

4. GARAGE STORAGE CABINETS: Large "BOX" stores carry these type of storage cabinets. They are surprisingly durable, and very low cost. They are not recommended for office use or high impact kitchen use, but you will see them in projects installed by owners because of the attractive cost factor and the quick delivery method.

5. KITCHEN ON STEROIDS: Everyone has walked into the box stores and seen the elaborate designs available for a beautiful kitchen area. Many of our church clients will upgrade to a more decorative cabinet system to make the kitchen feel like a home or residence. Some of our business offices will also make their breakroom kitchen areas a place worthy of a break.

Other things that are design considerations would be knobs, hardware, glazing, storage needs, plumbing, ventilation, etc. Working with our design experts we help you make an educated design choice for the best value on your project.

For more information contact our team at:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright, trademark ©

When we work with our clients during the commissioning or preconstruction phase we talk through a variety of questions to help them decide what is the best fit for their long and short term goals, and what is the best solution to meet cabinet and storage needs.

(5) Most Common Cabinet Types:

1. PREFABRICATED: This term is commonly used when there is a thin paper veneer over a compressed wood product and this is the face of your cabinets. For a really tight budget, very compressed schedule, or a low use area this type of cabinet will fit the use.

2. ALL WOOD FACED DOORS: This type of cabinet is attractive, and durable great for offices or standard daily use. They can be found "in-stock" or can be custom order depending on selection. The pricing is moderate but overall a good investment.

3. LAMINATE CABINETS: Laminate cabinets are commonly found in medical labs or doctors offices. They are washable and non-porous so they make a great "clean" option to store medical supplies. The cost is on the higher end, but when purchased from a quality manufacturer they will endure. They are usually custom order so allow a little more time in the schedule for this type of cabinet.

4. GARAGE STORAGE CABINETS: Large "BOX" stores carry these type of storage cabinets. They are surprisingly durable, and very low cost. They are not recommended for office use or high impact kitchen use, but you will see them in projects installed by owners because of the attractive cost factor and the quick delivery method.

5. KITCHEN ON STEROIDS: Everyone has walked into the box stores and seen the elaborate designs available for a beautiful kitchen area. Many of our church clients will upgrade to a more decorative cabinet system to make the kitchen feel like a home or residence. Some of our business offices will also make their breakroom kitchen areas a place worthy of a break.

Other things that are design considerations would be knobs, hardware, glazing, storage needs, plumbing, ventilation, etc. Working with our design experts we help you make an educated design choice for the best value on your project.

For more information contact our team at:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright, trademark ©

Tuesday, November 11, 2014

Equipment Lease, Section 179 Tax Benefits-Before Year End!

It is getting time for businesses that run on a calendar fiscal year to consider equipment needs, and space planning for next year. There is a little known tax incentive Section 179 that allows greater tax benefits to small and midsize companies looking to expand.

There are strategic advantages to leasing a new our used modular building versus purchasing one.

The US government has put a program together, Section 179, specifically for small to mid-sized business owners allowing them to expense or deduct their full equipment purchases from the same year tax return or “gross income”. Modular Solutions, Ltd has great partners that can help structure a tailored finance agreement which will allow you to expense the full amount, 100% of the equipment on this year’s current tax documents and you have the flexibility to pay off the remaining equipment amount either quickly, in as little as 2 years or as long as 8 years!

Enhanced Expense Limits, Section 179, 2014

This year’s deduction limit, as of January has taken a dramatic drop. The maximum equipment cost that may be written off is $25,000. The maximum amount that your business can spend to qualify is $200,000 total on equipment. For brand new equipment only, the bonus depreciation rate is 50%. However we are remaining optimistic that legistaltion may increase limits before year end.

Section 179 Background

Section 179 was originally referred to as the “SUV/Hummer deduction.” It was used to offset the cost of an SUV or business vehicle costs, which was included in the “Stimulus Act.” The Stimulus Act was created to improve the economy and although it continues to change, it is the most beneficial tax benefit for small businesses in particular.

Qualifying Property

The property must be Tangible Personal Property, and must be used for the business at a rate greater than 50%. New or used equipment is accepted. It is probable that businesses purchase Tangible Personal Property consistently: Equipment (machines, etc.), modular buildings, manufacturing tools, vehicles, software, and furniture.

Section 179 Tax Deduction is filed under IRS form 4562.Don’t forget to keep complete records of; lease agreement, purchasing details, acquired & delivery details of your business equipment!

*Tax information provided above is intended for educational purposes only. Please consult tax attorney for expert advice.* Leasing information courtesy of ILS one of our great leasing partners.

For more information contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

There are strategic advantages to leasing a new our used modular building versus purchasing one.

The US government has put a program together, Section 179, specifically for small to mid-sized business owners allowing them to expense or deduct their full equipment purchases from the same year tax return or “gross income”. Modular Solutions, Ltd has great partners that can help structure a tailored finance agreement which will allow you to expense the full amount, 100% of the equipment on this year’s current tax documents and you have the flexibility to pay off the remaining equipment amount either quickly, in as little as 2 years or as long as 8 years!

Enhanced Expense Limits, Section 179, 2014

This year’s deduction limit, as of January has taken a dramatic drop. The maximum equipment cost that may be written off is $25,000. The maximum amount that your business can spend to qualify is $200,000 total on equipment. For brand new equipment only, the bonus depreciation rate is 50%. However we are remaining optimistic that legistaltion may increase limits before year end.

Section 179 Background

Section 179 was originally referred to as the “SUV/Hummer deduction.” It was used to offset the cost of an SUV or business vehicle costs, which was included in the “Stimulus Act.” The Stimulus Act was created to improve the economy and although it continues to change, it is the most beneficial tax benefit for small businesses in particular.

Qualifying Property

The property must be Tangible Personal Property, and must be used for the business at a rate greater than 50%. New or used equipment is accepted. It is probable that businesses purchase Tangible Personal Property consistently: Equipment (machines, etc.), modular buildings, manufacturing tools, vehicles, software, and furniture.

Section 179 Tax Deduction is filed under IRS form 4562.Don’t forget to keep complete records of; lease agreement, purchasing details, acquired & delivery details of your business equipment!

*Tax information provided above is intended for educational purposes only. Please consult tax attorney for expert advice.* Leasing information courtesy of ILS one of our great leasing partners.

For more information contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

Monday, November 3, 2014

What Is A Purchasing Cooperative?

According to widipedia, A purchasing cooperative is a type of cooperative arrangement, to combine buying power to get lower prices from selected suppliers. Purchasing Cooperatives are used most frequently by governmental entities, since they are required to follow laws requiring competitive bidding above certain thresholds. Counties, municipalities, schools, colleges and universities in the majority of states can sign an interlocal agreement or contract that allows them to legally use a contract that was procured by another governmental entity.

What types of commodity are there? There are various types of commodities. Purchasing rules vary from state to state so many purchasing commodities choose to make a Statewide offering. For example CES of NEW MEXICO offers suppliers and services to local or state agencies who wants to be a free member of the commodity and take advantage of the time and financial savings realized throughout the state of New Mexico. The goal of CES is to provide superior services through strategic partners.

Other commodities make offerings to federal agencies. For example GSA is a national commodity, that any federal agency can purchase goods or services. Some state and local agencies recognize GSA, and others do not. The state procurement regulations dictate availability of this on a local/state basis.

Modular Solutions, Ltd is a procurement partner on the CES and GSA Schedule.

For more information on purchasing modular buildings through a commodity contract visit our team for a FREE consultation!

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright, trademark ©

What types of commodity are there? There are various types of commodities. Purchasing rules vary from state to state so many purchasing commodities choose to make a Statewide offering. For example CES of NEW MEXICO offers suppliers and services to local or state agencies who wants to be a free member of the commodity and take advantage of the time and financial savings realized throughout the state of New Mexico. The goal of CES is to provide superior services through strategic partners.

Other commodities make offerings to federal agencies. For example GSA is a national commodity, that any federal agency can purchase goods or services. Some state and local agencies recognize GSA, and others do not. The state procurement regulations dictate availability of this on a local/state basis.

Modular Solutions, Ltd is a procurement partner on the CES and GSA Schedule.

For more information on purchasing modular buildings through a commodity contract visit our team for a FREE consultation!

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright, trademark ©

Wednesday, October 29, 2014

Cost Effective Designs To Get A Higher Ceiling

One question we frequently hear is how do I get a higher ceiling in my modular building? Some uses like worship facilities, or multipurpose rooms, or physical activity spaces need a higher ceiling to effectively service the space goals.

The Challenge:

When a modular building gets over 15' or 16' high in most states, the transport gets extremely cost prohibitive. This reduces the cost savings that are realized by choosing modular construction. Our clients have come to us with this challenge and Modular Solutions, Ltd has come up with some cost-effective design solutions that help keep the transport fees affordable, and help keep the overall budget of the project in line with original cost projections.

1. Telescoping Roof: A telescoping roof system is one that is raised when it arrives on site allowing the building sections to transport down the road for the lower delivery costs, and still gain the additional ceiling height once the building is installed on site.

2. Hinged Roof: A hinged roof system is similar to a telescoping roof. This is common for smaller structures that are only two or three sections to obtain a nice high pitch in snow country.

3. Site Installed Stacks: Installing sections on top of each other with proper foundation and crane rigging on site saves time and money by allowing high roof sections to be set on each other with proper design & engineering details.

4. Clearspan Beams: Open up the ceiling and use a decorative steel duct system so it can be exposed allowing the roof beams and duct work to be open, like in a warehouse or restaurant setting. This picks up 1-2 additional feet in the ceiling height.

These are just a few of the creative and innovative solutions Modular Solutions, Ltd has developed for clients that have the need for additional ceiling height in a modular building structure.

For more information regarding how to design innovative space solutions contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1 (sales)

Email: Information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved copyright, trademark

The Challenge:

When a modular building gets over 15' or 16' high in most states, the transport gets extremely cost prohibitive. This reduces the cost savings that are realized by choosing modular construction. Our clients have come to us with this challenge and Modular Solutions, Ltd has come up with some cost-effective design solutions that help keep the transport fees affordable, and help keep the overall budget of the project in line with original cost projections.

1. Telescoping Roof: A telescoping roof system is one that is raised when it arrives on site allowing the building sections to transport down the road for the lower delivery costs, and still gain the additional ceiling height once the building is installed on site.

2. Hinged Roof: A hinged roof system is similar to a telescoping roof. This is common for smaller structures that are only two or three sections to obtain a nice high pitch in snow country.

3. Site Installed Stacks: Installing sections on top of each other with proper foundation and crane rigging on site saves time and money by allowing high roof sections to be set on each other with proper design & engineering details.

4. Clearspan Beams: Open up the ceiling and use a decorative steel duct system so it can be exposed allowing the roof beams and duct work to be open, like in a warehouse or restaurant setting. This picks up 1-2 additional feet in the ceiling height.

These are just a few of the creative and innovative solutions Modular Solutions, Ltd has developed for clients that have the need for additional ceiling height in a modular building structure.

For more information regarding how to design innovative space solutions contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1 (sales)

Email: Information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved copyright, trademark

Thursday, October 23, 2014

Fire Safety, What is NFPA 285?

Modular Buildings and Site Built Structures, should be built in accordance with safety in mind!

Understanding What is NFPA 285

In 1998, the National Fire Protection Association (NFPA) established the NFPA 285 “Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Non-Load-Bearing Wall Assemblies Containing Combustible Components.” NFPA 285 provides a determination of vertical fire performance for exterior wall assemblies, which is verified by actual testing. It is intended to help builders reduce the potential for upward spread of fire through wall.

The requirement for a weather-resistive barrier is as follows:

WRB (Weather-Resistive Barrier) Code Requirement: 1403.5 Vertical and Lateral Flame Propagation – Exterior walls on buildings of Type I, II, III, or IV construction that are greater than 40 feet (12.192m) in height above grade plane, and contain a combustible water-resistive barrier, shall be tested in accordance with, and comply with the acceptance criteria of NFPA 285.

For this reason, Modular Solutions, Ltd partners with companies such as DuPont™ Tyvek® air and water barriers designed for commercial construction because they have been tested and shown to meet NFPA 285, the National Fire Protection Association fire performance standard for vertical wall assemblies.

For more information on fire safety in multistory modular construction consult our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1 (sales)

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutionsltd

all rights reserved, copyright trademark ©

Understanding What is NFPA 285

In 1998, the National Fire Protection Association (NFPA) established the NFPA 285 “Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Non-Load-Bearing Wall Assemblies Containing Combustible Components.” NFPA 285 provides a determination of vertical fire performance for exterior wall assemblies, which is verified by actual testing. It is intended to help builders reduce the potential for upward spread of fire through wall.

The requirement for a weather-resistive barrier is as follows:

WRB (Weather-Resistive Barrier) Code Requirement: 1403.5 Vertical and Lateral Flame Propagation – Exterior walls on buildings of Type I, II, III, or IV construction that are greater than 40 feet (12.192m) in height above grade plane, and contain a combustible water-resistive barrier, shall be tested in accordance with, and comply with the acceptance criteria of NFPA 285.

For this reason, Modular Solutions, Ltd partners with companies such as DuPont™ Tyvek® air and water barriers designed for commercial construction because they have been tested and shown to meet NFPA 285, the National Fire Protection Association fire performance standard for vertical wall assemblies.

For more information on fire safety in multistory modular construction consult our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1 (sales)

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutionsltd

all rights reserved, copyright trademark ©

Friday, October 17, 2014

What Will Your Modular Building Be For Halloween?

Sometimes it is fun to forget the formalities and just have fun with your decorating. Modular buildings can easily transform into seasonal decorations with a few quick easy tricks (or treats)

TIPS FOR DECORATING YOUR MODULAR BUILDING:

1) A little goes a long way, if you are a business you don't want to scare the neighbors and children too badly

2) Use materials that can be easily removed. Traces of spider webs and hay bails are reminders of Halloween past

3) Pick a theme and keep it simple (pumpkins or ghosts or candy corns) using items you don't remind replacing if someone likes your decorating idea too much

4) Lighting can create an ambiance. There are a variety of rope lights and solar lights available to help create a fun atmosphere

5) Keep it SAFE. Halloween is meant to be fun and an accident or mishap can hurt your image and pocketbook.

Have a safe & great Halloween from Modular Solutions, Ltd

all rights reserved copyright, trademark 2014 ©

TIPS FOR DECORATING YOUR MODULAR BUILDING:

1) A little goes a long way, if you are a business you don't want to scare the neighbors and children too badly

2) Use materials that can be easily removed. Traces of spider webs and hay bails are reminders of Halloween past

3) Pick a theme and keep it simple (pumpkins or ghosts or candy corns) using items you don't remind replacing if someone likes your decorating idea too much

4) Lighting can create an ambiance. There are a variety of rope lights and solar lights available to help create a fun atmosphere

5) Keep it SAFE. Halloween is meant to be fun and an accident or mishap can hurt your image and pocketbook.

Have a safe & great Halloween from Modular Solutions, Ltd

all rights reserved copyright, trademark 2014 ©

Tuesday, October 14, 2014

What Services Can A Modular Company Provide?

Modular companies show lots of great looking finished modular building projects on their websites with pretty landscape, and extravagant porches, and mixed traditional and modular construction. One great question we hear is "how much of that project did you complete"? Here is a summary of the different types of companies in the modular industry. Of course all of this information is "TYPICAL" however it is good resource for anyone interested in purchasing a modular building, and will help you do your homework & see how the seller is licensed and what services they can legally provide.

Another great reason to get a physical copy of a license is to research the license history and validity.

* DEALER: A dealer buys and sells modular buildings from other people. Mostly "stock" units with industry standard finishes, some are licensed to install the buildings many only can sell modular buildings. Dealers are generally not licensed to do any site work.

* GENERAL CONTRACTOR: A general contractor hires a modular building company to build or fabricate the modular building and then provides the site work & finishes to complete the building. A general contractor does not usually do any design work or fabricate modular buildings. A general contractor does not usually have architectural services.

* CONSTRUCTION MANAGER: A construction manager is a logistics partner. They usually have some background in management of projects but are not usually licensed to handle any of the specific construction work. They typically get a percentage of the contract amount to oversee a general contractor, manufacturer, architect and dealer offering management advise along the way.

*ARCHITECT: An architect has to be licensed in the state they are drawing for. An architect can design the modular building, but sometimes is they are not aware of the special criteria it takes to design a modular building in sections and how to keep it affordable.

*MANUFACTURER: A modular building manufacturer usually sells to a dealer, or a general contractor. The manufacturers' responsibility stops at the factory door, and within the confines of the box. Sometimes when a wholesale manufacturer sells a building to a dealer there are gray areas that get overlooked or missed.

DESIGN-BUILD FACTORY DIRECT ARCHITECTURAL/GENERAL CONTRACTOR/MANUFACTURER: Modular Solutions, Ltd is a design-build general contractor that specializes in modular buildings. By working with clients from inception we are able to provide architectural design, site work and general contracting responsibilities, and control the entire process in our manufacturing facility. When you work with Modular Solutions, Ltd you are getting the experts in every field under one roof.

The best way to determine if a modular building company can provide you with everything you need to get a temporary or permanent modular building installed is to ask for their licenses. See how far they can legally take your project and how much will they complete for you.

For more information on modular building construction contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1 (Sales)

Email: information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved, copyright, trademark 2014 ©

Another great reason to get a physical copy of a license is to research the license history and validity.

* DEALER: A dealer buys and sells modular buildings from other people. Mostly "stock" units with industry standard finishes, some are licensed to install the buildings many only can sell modular buildings. Dealers are generally not licensed to do any site work.

* GENERAL CONTRACTOR: A general contractor hires a modular building company to build or fabricate the modular building and then provides the site work & finishes to complete the building. A general contractor does not usually do any design work or fabricate modular buildings. A general contractor does not usually have architectural services.

* CONSTRUCTION MANAGER: A construction manager is a logistics partner. They usually have some background in management of projects but are not usually licensed to handle any of the specific construction work. They typically get a percentage of the contract amount to oversee a general contractor, manufacturer, architect and dealer offering management advise along the way.

*ARCHITECT: An architect has to be licensed in the state they are drawing for. An architect can design the modular building, but sometimes is they are not aware of the special criteria it takes to design a modular building in sections and how to keep it affordable.

*MANUFACTURER: A modular building manufacturer usually sells to a dealer, or a general contractor. The manufacturers' responsibility stops at the factory door, and within the confines of the box. Sometimes when a wholesale manufacturer sells a building to a dealer there are gray areas that get overlooked or missed.

DESIGN-BUILD FACTORY DIRECT ARCHITECTURAL/GENERAL CONTRACTOR/MANUFACTURER: Modular Solutions, Ltd is a design-build general contractor that specializes in modular buildings. By working with clients from inception we are able to provide architectural design, site work and general contracting responsibilities, and control the entire process in our manufacturing facility. When you work with Modular Solutions, Ltd you are getting the experts in every field under one roof.

The best way to determine if a modular building company can provide you with everything you need to get a temporary or permanent modular building installed is to ask for their licenses. See how far they can legally take your project and how much will they complete for you.

For more information on modular building construction contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1 (Sales)

Email: information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved, copyright, trademark 2014 ©

Friday, October 3, 2014

Employee Housing, How To Keep It Affordable Five Easy Tips

You have a school district or clinic 50 miles from the next closest town, and all the surrounding land is federal or tribal so the question arises- Where will our employees live?

How can we keep our employees local and give them good living facilities - the answer is easy!

Build modular housing.

The oil and gas & railroad industries have been building remote housing and recreational facilities for their employees for years. The difference between those industries and education or medical housing is that a large majority of educational and medical staff are married with children. The old "bunkhouse" mentality does not work for this type of employee housing. A general study has proven that absenteeism and job hopping has been lowered by having affordable and attractive housing available on site for the employees.

FIVE EASY TIPS:

1. Keep the housing near the clinic or school. By using existing infrastructure you can keep the costs lower and employees will be minutes from work.

2. Design multiple plans. By accommodating 1,2,&3 br footprints you are able to save space when a smaller family is hired and have ample room for larger families. Some of our clients even choose single family homes so if a really large family moves in they can have sufficient space.

3. Don't be afraid to "GO-UP". Multistory facilities can save land use if you are in an area where available space is tight.

4. Keep it simple. When you choose prefabricated, try to find "existing" plans to work with. Sometimes creating custom or special order plans are fun, but can cost more money than choosing designs that have worked for other employee housing locations.

5. Build housing that is sustainable, green and that has extended life cycle. An employee looks at the total cost to stay, and high utility bills are a contributing factor. By designing smart and helping the environment you will build a community that will last and be attractive for many generations to come.

For more information on employee housing contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

Facebook: www.facebook.com/modularsolutionsltd

all rights reserved copyright, trademark ©

How can we keep our employees local and give them good living facilities - the answer is easy!

Build modular housing.

The oil and gas & railroad industries have been building remote housing and recreational facilities for their employees for years. The difference between those industries and education or medical housing is that a large majority of educational and medical staff are married with children. The old "bunkhouse" mentality does not work for this type of employee housing. A general study has proven that absenteeism and job hopping has been lowered by having affordable and attractive housing available on site for the employees.

FIVE EASY TIPS:

1. Keep the housing near the clinic or school. By using existing infrastructure you can keep the costs lower and employees will be minutes from work.

2. Design multiple plans. By accommodating 1,2,&3 br footprints you are able to save space when a smaller family is hired and have ample room for larger families. Some of our clients even choose single family homes so if a really large family moves in they can have sufficient space.

3. Don't be afraid to "GO-UP". Multistory facilities can save land use if you are in an area where available space is tight.

4. Keep it simple. When you choose prefabricated, try to find "existing" plans to work with. Sometimes creating custom or special order plans are fun, but can cost more money than choosing designs that have worked for other employee housing locations.

5. Build housing that is sustainable, green and that has extended life cycle. An employee looks at the total cost to stay, and high utility bills are a contributing factor. By designing smart and helping the environment you will build a community that will last and be attractive for many generations to come.

For more information on employee housing contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

Facebook: www.facebook.com/modularsolutionsltd

all rights reserved copyright, trademark ©

Tuesday, September 30, 2014

Box On Wheels, Isn't That What A Modular Building Is?

One comment that the modular industry hears frequently is "I don't want a trailer, it is just a box on wheels". Our goal is help you understand that while some companies in the modular industry still design and sell a "box-on-wheels" there is so much more available. Companies like Modular Solutions, LTD take pride in having an architectural staff, and building permanent structures that have 50+ year life cycles, and are sustainable and good for the environment.

I have been in the modular industry since the 80's and it has been great to see the pioneers in the industry that have built hotels, hospitals, military dormitories, and all types of permanent structures with great structural and aesthetic upgrades. Modular Solutions, Ltd has been a member of the modular building institute that showcases projects in our industry that push the envelope of creativity, and really take modular projects to a new level. There is no reason to settle, when you can have the very best.

For more information on permanent modular construction contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

facebook: www.facebook.com/modularsolutionsltd

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark 2014

I have been in the modular industry since the 80's and it has been great to see the pioneers in the industry that have built hotels, hospitals, military dormitories, and all types of permanent structures with great structural and aesthetic upgrades. Modular Solutions, Ltd has been a member of the modular building institute that showcases projects in our industry that push the envelope of creativity, and really take modular projects to a new level. There is no reason to settle, when you can have the very best.

For more information on permanent modular construction contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

facebook: www.facebook.com/modularsolutionsltd

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark 2014

Friday, September 26, 2014

Emergency Space Solutions, After A Flood

The Glendale Union High School District experienced torrential rain storms, causing flood conditions. When they needed emergency space they came to Modular Solutions, Ltd in Phoenix. Our team has (6) classrooms in inventory that were ready to ship and set in place. By working closely with their site contractor McCarthy Construction and with the District Modular Solutions, Ltd was able to get emergency classrooms open for children in a matter of days.

The local and state building officials and Fire Marshall had to expedite the approval and placement policy to get the buildings approved for occupancy. This is a great example of what can be accomplished when you have a great team in place and everyone has a "can-do" attitude.

For more information on emergency modular building facilities contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1 (Sales)

Email: Information@Mod-sol.com

Website: www.ModularSolutionsLtd.com

all rights reserved copyright, trademark 2014 ©

The local and state building officials and Fire Marshall had to expedite the approval and placement policy to get the buildings approved for occupancy. This is a great example of what can be accomplished when you have a great team in place and everyone has a "can-do" attitude.

For more information on emergency modular building facilities contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1 (Sales)

Email: Information@Mod-sol.com

Website: www.ModularSolutionsLtd.com

all rights reserved copyright, trademark 2014 ©

Monday, September 22, 2014

Indoor Air Quality, What Is That?

One phrase that has been seen more in the modular building industry lately is "indoor Air Quality". What does that really mean?

Indoor air quality (IAQ) simply refers to the air quality within modular and traditional constructed buildings and structures. IAQ usually relates to the health and comfort of building occupants. IAQ can be affected by gases (including carbon monoxide, radon, volatile organic compounds), particulates, microbial contaminants (mold, bacteria), or any mass or energy stressor that can induce adverse health conditions. In most cases buildings being utilized for classroom or office use can be brought up to current standards by updating fresh air standards. Some occupants can be sensitive to the gases in a building (traditional or modular), and need special corrections.

When a project is LEED the category this usually falls under is Indoor Environmental Quality (IEQ). This is only one of the categories, that LEED uses as a standard to provide comfort, well-being, and productivity of the building occupants. The LEED IEQ category helps address design and construction guidelines pertaining to: indoor air quality (IAQ), thermal quality, and lighting quality.

Proper building ventilation, fresh air, windows, natural & electric lighting, VOC or gas emissions, all fall under the environmental conditions inside a modular or traditional structure.

For more information on proper indoor air quality levels and design contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright trademark 2014©

Indoor air quality (IAQ) simply refers to the air quality within modular and traditional constructed buildings and structures. IAQ usually relates to the health and comfort of building occupants. IAQ can be affected by gases (including carbon monoxide, radon, volatile organic compounds), particulates, microbial contaminants (mold, bacteria), or any mass or energy stressor that can induce adverse health conditions. In most cases buildings being utilized for classroom or office use can be brought up to current standards by updating fresh air standards. Some occupants can be sensitive to the gases in a building (traditional or modular), and need special corrections.

When a project is LEED the category this usually falls under is Indoor Environmental Quality (IEQ). This is only one of the categories, that LEED uses as a standard to provide comfort, well-being, and productivity of the building occupants. The LEED IEQ category helps address design and construction guidelines pertaining to: indoor air quality (IAQ), thermal quality, and lighting quality.

Proper building ventilation, fresh air, windows, natural & electric lighting, VOC or gas emissions, all fall under the environmental conditions inside a modular or traditional structure.

For more information on proper indoor air quality levels and design contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved, copyright trademark 2014©

Monday, September 15, 2014

We Need Worship Space...HELP!

Worship space is very common in the modular industry. Churches and religious organizations that are growing, but not enough to build their permanent structure are looking for ways to save money and time. By using a modular building as a semi-permanent space solution the church can continue to grow and be a part of a community without having to be a "church-in-a-box" where they lease space and pack and unpack their belongings every week.

What options are available for small religious communities?

1. Lease a previously leased modular building. They payments are affordable, and the building can be installed fairly quick. When you are done you just turn it back in.

2. Purchase a previously leased modular building. If you save up for a short period of time you will find the used modular buildings are less expensive than new

3. Lease/Purchase a previously leased modular building. This is a great way if you are planning on keeping the building for other uses when the permanent building goes in.

Semi-permanent modular buildings are a bridge between meeting on your home campus, and having your dream building.

The great thing about choosing Modular Solutions, Ltd for this type of building is we can also build the permanent building when you are ready (from inception - final warranty)

Get to know our great team at Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark ©

What options are available for small religious communities?

1. Lease a previously leased modular building. They payments are affordable, and the building can be installed fairly quick. When you are done you just turn it back in.

2. Purchase a previously leased modular building. If you save up for a short period of time you will find the used modular buildings are less expensive than new

3. Lease/Purchase a previously leased modular building. This is a great way if you are planning on keeping the building for other uses when the permanent building goes in.

Semi-permanent modular buildings are a bridge between meeting on your home campus, and having your dream building.

The great thing about choosing Modular Solutions, Ltd for this type of building is we can also build the permanent building when you are ready (from inception - final warranty)

Get to know our great team at Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark ©

Friday, September 12, 2014

Do Modular Buildings Have Safe VOC Levels?

A fairly new acronym in the construction and green industry is Volatile organic compounds (VOCs) They are organic chemicals that have a high vapor pressure at ordinary room temperature. Their high vapor pressure results from a low boiling point, which causes large numbers of molecules to evaporate or sublimate from the liquid or solid form of the compound and enter the surrounding air.

Where is VOC in a building?VOC's usually come from things like paint, carpet glue, wall glue, cleaning solvents and other components within a building. VOCs can sometimes cause symptoms to those that are sensitive, including headaches and dizziness. The federal government has strictly regulated the levels that are considered allowable by each industry. For example, The federal government caps the VOC content in paint at 250 grams per liter (g/l) for flat finishes and 380 g/l for other finishes (low-luster, semigloss, etc.). This is the standard that many companies utilize. HOWEVER there are companies that have invested into developing NO VOC paints. You can find those in chain stores and on line.

How do we get low or no VOC?VOC content is something that does not effect most of the population today because suppliers are making their formulas different to comply with federal guidelines, but you can specifically ask for a low or NO VOC content building and specify how and where you want that to occur. By doing your homework you can call out the brands and type of products you want in your modular building.

Look for the logos

What if we don't know what to choose?By hiring a professional modular building company such as Modular Solutions, Ltd you can work with the design & preconstruction team to ensure you are getting an environmentally friendly and safe building.

For more information with VOCs and other environmental issues on modular buildings contact our team at:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark ©

Where is VOC in a building?VOC's usually come from things like paint, carpet glue, wall glue, cleaning solvents and other components within a building. VOCs can sometimes cause symptoms to those that are sensitive, including headaches and dizziness. The federal government has strictly regulated the levels that are considered allowable by each industry. For example, The federal government caps the VOC content in paint at 250 grams per liter (g/l) for flat finishes and 380 g/l for other finishes (low-luster, semigloss, etc.). This is the standard that many companies utilize. HOWEVER there are companies that have invested into developing NO VOC paints. You can find those in chain stores and on line.

How do we get low or no VOC?VOC content is something that does not effect most of the population today because suppliers are making their formulas different to comply with federal guidelines, but you can specifically ask for a low or NO VOC content building and specify how and where you want that to occur. By doing your homework you can call out the brands and type of products you want in your modular building.

Look for the logos

What if we don't know what to choose?By hiring a professional modular building company such as Modular Solutions, Ltd you can work with the design & preconstruction team to ensure you are getting an environmentally friendly and safe building.

For more information with VOCs and other environmental issues on modular buildings contact our team at:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark ©

Tuesday, September 9, 2014

Modular Solutions, Ltd Helps The Mail Get Delivered!

Modular Solutions, Ltd has been in business since 1996. Our team has helped the US Postal service with temporary and permanent space needs. Many of the smaller more rural areas just have a counter and a secured sorting area in the back to take care of local customers. Our team helps build modular buildings that meet the strict USPS construction guidelines, and build modular post office facilities and work areas.

The heavy sorting machines require an upgraded floor, and a secured entry to ensure your letters, cards, and important mail items successfully deliver

Special construction is incorporated into the secured area of the facility

Fun lap siding is added to the exterior to blend into the existing community aesthetics

A turnkey approach was taken, taking care of the site work and permits required

The USPS utilized our GSA contract, enabling them to save time and money

For more information contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: Information@mod-sol.com

website: www.modularsolutionsltd.com

Facebook: www.facebook.com/modularsolutionsltd

all rights reserved copyright, trademark 2014 ©

The heavy sorting machines require an upgraded floor, and a secured entry to ensure your letters, cards, and important mail items successfully deliver

Special construction is incorporated into the secured area of the facility

Fun lap siding is added to the exterior to blend into the existing community aesthetics

A turnkey approach was taken, taking care of the site work and permits required

The USPS utilized our GSA contract, enabling them to save time and money

For more information contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: Information@mod-sol.com

website: www.modularsolutionsltd.com

Facebook: www.facebook.com/modularsolutionsltd

all rights reserved copyright, trademark 2014 ©

Wednesday, September 3, 2014

Modular Solutions Is An Amigo

Are you a supporter of the mining industry? Modular Solutions, Ltd is! Modular Solutions, Ltd is a proud member of AMIGOS an advocate for environmentally sound mining practices, and also Arizona Mining Association. The southwest can attribute many jobs, and secondary affiliated jobs as a result of the mining industry. Modular buildings and steel buildings are frequently used for space solutions in the mining industry.

To work on a mine site your team must have special industry training & certification from MSHA. Modular Solutions, Ltd is ready to spring into action on any mining site with our MSHA certified project teams. We have provided concrete work, steel buildings, modular buildings, and other projects for our mining organization partners.

FOR MORE INFORMATION CONTACT US:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved copyright, trademark 2014©

To work on a mine site your team must have special industry training & certification from MSHA. Modular Solutions, Ltd is ready to spring into action on any mining site with our MSHA certified project teams. We have provided concrete work, steel buildings, modular buildings, and other projects for our mining organization partners.

FOR MORE INFORMATION CONTACT US:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved copyright, trademark 2014©

Wednesday, August 27, 2014

Back To School Modular Building Safety Tips

Each year as kids head back to school in modular and portable classroom buildings there are instances of unsafe site conditions. Here are a few tips to keep your project site safer and keep the children and staff out of the nurses office with avoidable accidents:

( 5 ) Great tips for safety:

1. If you have wall mounted mechanical units that usually sit 4' - 5' off the ground implement safety plan:

* Build a cage or designer box around the mechanical units (pretty also)

* Put in pipe bollards painted yellow to warn pedestrian traffic of possible danger

* Pull your sidewalks and walkways away from the modular building a minimum of 3' to remove the pedestrian pathway away from the mechanical units

2. If you have a ramp, make sure there is no rust or broken sharp edges that can cut or hurt someone

2A. Do a preventative walk through of your ramp & stair attachments & make sure the railings are attached, the welds are tight, skid resistant material fresh coating.

3. If your doors swing "out" paint a circle on the sidewalks so kids and staff can visualize the swing radius

4. If you have traditional steel doors consider adding a "view lite" small window so when opening a door you can see oncoming pedestrian traffic

5. Of course, the traditional fire alarm,fire sprinkler, & extinguisher equipment need to pass annual inspections

For more information contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: Information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved copyright, trademark © 2014

( 5 ) Great tips for safety:

1. If you have wall mounted mechanical units that usually sit 4' - 5' off the ground implement safety plan:

* Build a cage or designer box around the mechanical units (pretty also)

* Put in pipe bollards painted yellow to warn pedestrian traffic of possible danger

* Pull your sidewalks and walkways away from the modular building a minimum of 3' to remove the pedestrian pathway away from the mechanical units

2. If you have a ramp, make sure there is no rust or broken sharp edges that can cut or hurt someone

2A. Do a preventative walk through of your ramp & stair attachments & make sure the railings are attached, the welds are tight, skid resistant material fresh coating.

3. If your doors swing "out" paint a circle on the sidewalks so kids and staff can visualize the swing radius

4. If you have traditional steel doors consider adding a "view lite" small window so when opening a door you can see oncoming pedestrian traffic

5. Of course, the traditional fire alarm,fire sprinkler, & extinguisher equipment need to pass annual inspections

For more information contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: Information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved copyright, trademark © 2014

Tuesday, August 26, 2014

Back To School, In A New Modular School

It is that time of year and the new school year is well underway in many locations. Schools are in session from head start to university level education. Many of those schools are back in session, in a modular building, or a modular campus. FLOOR PLAN LINK

Modular buildings are used for temporary overflow classrooms, and also as a permanent space solution. No matter what type of modular building is on your campus you can feel secure knowing the IBC construction code is incorporated into every new modular building going to a school campus. What type of modular buildings are on a school campus?

1. Traditional classrooms for 20 - 35 students each.

2. Science laboratories for accelerating STEM education

3. Computer learning labs, with advanced technologies

4. Vocational training labs (cosmetology, culinary arts,vehicle shop, etc)

5. Daycare and infant care centers

6. Lecture halls and conference centers

7. Cafeteria, food service, multipurpose facilities

8. Sports centers (gymnasium, locker rooms)

9. Specialty classroom (arts, music)

10. Administration offices

11. Bus barns and service bays

12. Guard Shacks/Security Booths

13. Health care and wellness centers or nursing stations

14. On line learning centers

No matter what the space need is on an educational campus, there is a Modular Solution!

For more information contact our team:

Modular Solutions, Ltd

P O Box 15507-Phoenix, AZ 85060

Phone: 800-441-8577 ext. 1

email: Information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark 2014 ©

Modular buildings are used for temporary overflow classrooms, and also as a permanent space solution. No matter what type of modular building is on your campus you can feel secure knowing the IBC construction code is incorporated into every new modular building going to a school campus. What type of modular buildings are on a school campus?

1. Traditional classrooms for 20 - 35 students each.

2. Science laboratories for accelerating STEM education

3. Computer learning labs, with advanced technologies

4. Vocational training labs (cosmetology, culinary arts,vehicle shop, etc)

5. Daycare and infant care centers

6. Lecture halls and conference centers

7. Cafeteria, food service, multipurpose facilities

8. Sports centers (gymnasium, locker rooms)

9. Specialty classroom (arts, music)

10. Administration offices

11. Bus barns and service bays

12. Guard Shacks/Security Booths

13. Health care and wellness centers or nursing stations

14. On line learning centers

No matter what the space need is on an educational campus, there is a Modular Solution!

For more information contact our team:

Modular Solutions, Ltd

P O Box 15507-Phoenix, AZ 85060

Phone: 800-441-8577 ext. 1

email: Information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark 2014 ©

Tuesday, August 19, 2014

Are Bars Safe?

Security is always an issue with any office facility. If you are rural you face weekend or passer by traffic stopping in to see what they can "borrow", if you are in a busy city you face the crime rates that goes along with being in a metropolitan area. One thing our clients are concerned about is what if they can not get out of a modular building in an emergency?

The key to security both internal and external is "DESIGN". Do not buy security bars from a vendor that will make your new facility look like a prison. We have found that there is an entire art to this industry. We work with one vendor , Desert Ornamental Artistry, and the reason we enjoy working with them is that they always provide decorative and creative solutions meeting the security aspects of a project without looking boring and common.

Some quick tips for design safety:

1. If you are getting an ornamental gate, have the door swing OUT. Safer for the occupant of a facility

2. If you are ordering security bars, make sure they have a "quick-release". This will release the bars in the

event of an internal safety issue such as fire or intruder.

3. Design your windows or at least one on a hallway large enough to use as an "egress" in an emergency. Small 12" tall windows are great for energy design,

but are not necessarily the best choice in an intruder situation.

4. Build your design creatively. Know that you have choices in the way the bars appear,

and how they are hung. You are not limited to vertical bars with mesh backing unless budget is your only concern.'

FOR MORE INFORMATION CONTACT OUR PRE-CONSTRUCITON TEAM:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: Information@mod-sol.com

Website: www.modularsolutionsltd.com

Linked In: ModularSolutionsLtd

all rights reserved, copyright, trademark 2014©

The key to security both internal and external is "DESIGN". Do not buy security bars from a vendor that will make your new facility look like a prison. We have found that there is an entire art to this industry. We work with one vendor , Desert Ornamental Artistry, and the reason we enjoy working with them is that they always provide decorative and creative solutions meeting the security aspects of a project without looking boring and common.

Some quick tips for design safety:

1. If you are getting an ornamental gate, have the door swing OUT. Safer for the occupant of a facility

2. If you are ordering security bars, make sure they have a "quick-release". This will release the bars in the

event of an internal safety issue such as fire or intruder.

3. Design your windows or at least one on a hallway large enough to use as an "egress" in an emergency. Small 12" tall windows are great for energy design,

but are not necessarily the best choice in an intruder situation.

4. Build your design creatively. Know that you have choices in the way the bars appear,

and how they are hung. You are not limited to vertical bars with mesh backing unless budget is your only concern.'

FOR MORE INFORMATION CONTACT OUR PRE-CONSTRUCITON TEAM:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: Information@mod-sol.com

Website: www.modularsolutionsltd.com

Linked In: ModularSolutionsLtd

all rights reserved, copyright, trademark 2014©

Friday, August 15, 2014

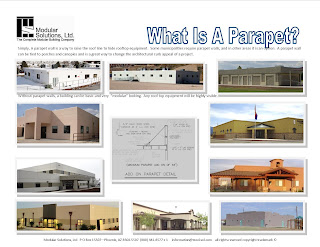

What Is A Parapet Wall?

When modular buildings are transported down the road they have to be within standard shipping heights allowed by the Department of Transportation. Additionally, sometimes the route to the project site has low overhead traffic lights or low bridges. Before any modular building goes down the road, the project manager will check the route to the site and see what type of height restrictions might be encountered, and if there is an alternative route. Modular companies that have a preconstruction team, will investigate these items during the design phase to avoid project surprises and expense.

What does all of this information have to do with a parapet wall? When clients want a higher profile modular building or have to hide mechanical roof top equipment they will add a parapet wall to raise the roof line and add architectural interest to the visual aspects of the modular building.

What is a parapet wall? The parapet wall can either be built on site, or in the plant, and is an addition that goes above he exterior perimeter walls. A parapet wall can be basic and squared off or a parapet wall can have fun architectural shapes. Parapet wall built in the plant will usually be 3' to 4' high so that the parapet walls can ship and install easily. Taller parapet walls are common but require additional design engineering.

For more information contact our team:

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark ©

What does all of this information have to do with a parapet wall? When clients want a higher profile modular building or have to hide mechanical roof top equipment they will add a parapet wall to raise the roof line and add architectural interest to the visual aspects of the modular building.

What is a parapet wall? The parapet wall can either be built on site, or in the plant, and is an addition that goes above he exterior perimeter walls. A parapet wall can be basic and squared off or a parapet wall can have fun architectural shapes. Parapet wall built in the plant will usually be 3' to 4' high so that the parapet walls can ship and install easily. Taller parapet walls are common but require additional design engineering.

For more information contact our team:

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

website: www.modularsolutionsltd.com

all rights reserved copyright, trademark ©

Tuesday, August 12, 2014

Great Answers Are Usually Predicated By Great Questions

I have had clients come to Modular Solutions that were confused and shared with me that design-build construction was just too hard and did not make sense. Some clients have spent as much on architectural design as they have on the actual modular building structure. By asking the right questions, we can work together and establish what is important in the overall total package.

There are (3) basic areas that need to be Collaborated on:

Space Planning Goals, Structural Goals, and Budget.

Once the basics of those areas have been addressed and talked through clients can make informed design choices that lead to a better building plan in the end.

For more information on design-build modular construction contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved copyright, trademark 2014©

There are (3) basic areas that need to be Collaborated on:

Space Planning Goals, Structural Goals, and Budget.

Once the basics of those areas have been addressed and talked through clients can make informed design choices that lead to a better building plan in the end.

For more information on design-build modular construction contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

Email: information@mod-sol.com

Website: www.modularsolutionsltd.com

all rights reserved copyright, trademark 2014©

Monday, August 11, 2014

Going Green, With An Existing Modular Building

How can you reduce your carbon footprint when you are in an existing modular building? Here are a few tips to reduce your carbon footprint in an existing modular building.

TIPS TO REDUCE YOUR CARBON FOOTPRINT:

For more tips or to get a NEW MODULAR SOLUTION, contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutionsltd

all rights reserved 2014 ©

TIPS TO REDUCE YOUR CARBON FOOTPRINT:

For more tips or to get a NEW MODULAR SOLUTION, contact our team:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

facebook: www.facebook.com/modularsolutionsltd

all rights reserved 2014 ©

Friday, August 8, 2014

GSA Advantage, Procurement Made Easy

If you are a federal agency and need space quickly, one of the best procurement tools is GSA advantage. Our Contract Number is GS-07F-0199L

How does GSA advantage work?

1. Find vendors and filter based on project qualifications (example geographic location, business size, reps & certs, etc)

2. Work out a scope or choose a design-build approach with best technical proposal winning the job

3. Set evaluation criteria to meet your goals (ie small business, disadvantaged enterprise, manufacturer, local preference, etc)

4. Post the notification and have all proposals back in within a few days or weeks (subject to technical criteria)

5. Pick your favorite team and get started!

Modular Solutions has successfully completed over $20M in GSA contracts with federal and eligible agencies.

If you need an experienced and professional team for the job team solutions is ABLE! On the GSA schedule since 2000!

Contact us:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

All rights reserved, copyright , trademark ©

How does GSA advantage work?

1. Find vendors and filter based on project qualifications (example geographic location, business size, reps & certs, etc)

2. Work out a scope or choose a design-build approach with best technical proposal winning the job

3. Set evaluation criteria to meet your goals (ie small business, disadvantaged enterprise, manufacturer, local preference, etc)

4. Post the notification and have all proposals back in within a few days or weeks (subject to technical criteria)

5. Pick your favorite team and get started!

Modular Solutions has successfully completed over $20M in GSA contracts with federal and eligible agencies.

If you need an experienced and professional team for the job team solutions is ABLE! On the GSA schedule since 2000!

Contact us:

Modular Solutions, Ltd

Phone: 800-441-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

All rights reserved, copyright , trademark ©

Wednesday, August 6, 2014

We Need Space NOW! Year End For Federal Agencies....

It is year end and you have a request for immediate swing space or for a temporary space solution.....don't worry- Modular Solutions, Ltd has a solution!

We have an inventory of modular buildings that can ship immediately based on your project location. For example we have a building that is 17,000 square ft in inventory right now. It is great for general administration, meeting space, swing space, or even for a permanent solution. This is a building that is 100% complete and returning from another client that no longer needs the space.

Team Solutions thoroughly renovates the building so it is fresh and clean & ready to move into in a matter of days. NO NEED TO WAIT - ORDER YOURS TODAY!

We know that every procurement is a priority at year end, our goal is to help you make the schedule, and find a durable and cost-effective design.

Ask about our special GSA pricing and delivery options. Ordering an "in-stock" modular solution is as easy as 1-2-3.

For more information contact our GSA team at:

Modular Solutions, Ltd

Phone (800) 441+-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

BLOG: WWW.MODULARSOLUTIONS.BLOGSPOT.COM

FACEBOOK: www.facebook.com/modularsolutionsltd

all rights reserved copyright, trademark ©

We have an inventory of modular buildings that can ship immediately based on your project location. For example we have a building that is 17,000 square ft in inventory right now. It is great for general administration, meeting space, swing space, or even for a permanent solution. This is a building that is 100% complete and returning from another client that no longer needs the space.

Team Solutions thoroughly renovates the building so it is fresh and clean & ready to move into in a matter of days. NO NEED TO WAIT - ORDER YOURS TODAY!

We know that every procurement is a priority at year end, our goal is to help you make the schedule, and find a durable and cost-effective design.

Ask about our special GSA pricing and delivery options. Ordering an "in-stock" modular solution is as easy as 1-2-3.

For more information contact our GSA team at:

Modular Solutions, Ltd

Phone (800) 441+-8577 x 1

email: information@mod-sol.com

website: www.modularsolutionsltd.com

BLOG: WWW.MODULARSOLUTIONS.BLOGSPOT.COM

FACEBOOK: www.facebook.com/modularsolutionsltd

all rights reserved copyright, trademark ©

Tuesday, August 5, 2014

What Does Life Cycle Mean?